How is the motor stator core made?

Motor manufacturing process:

1 Lathe axle.

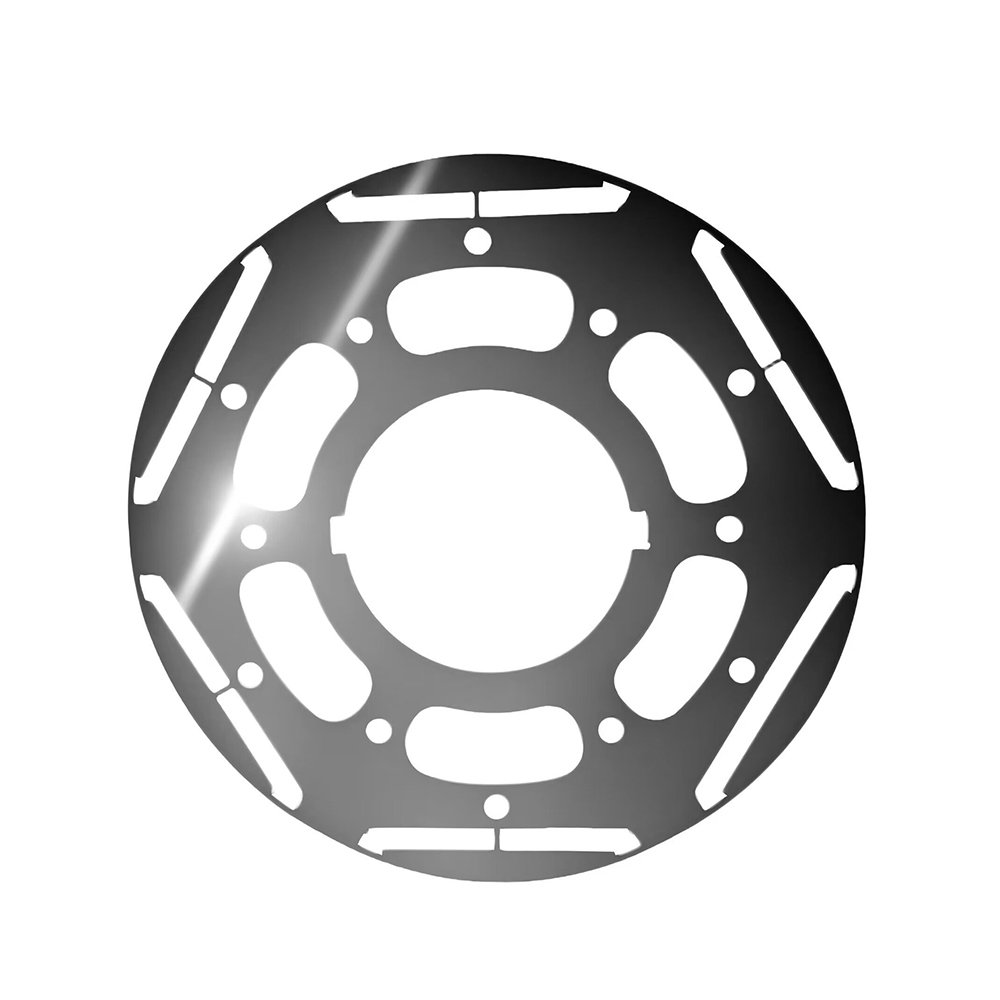

2 Punch out silicon steel sheets.

3 Melt stator aluminum in a large pot.

4 Die-casting machine die-casting.

5 Fine lathe polishing.

6 Seal and store in warehouse.

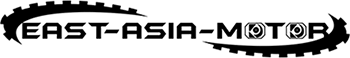

The stator core is an important component that constitutes the motor magnetic flux circuit and fixes the stator coil. It is composed of punching sheets and various fasteners pressed together to form a whole. Basic requirements for stator core:

1) Good magnetic conductivity and low loss.

2) Good rigidity and good vibration.

3) Good ventilation effect in structural layout.

4) The inner diameter and slot size of the core after lamination should meet the design accuracy requirements.

In addition, there are special requirements for large and large cores. For example, the gap between the split cores must be ensured, otherwise the core will vibrate when the motor is running. The thickness of the punching sheet is generally 0.5mm or 0.35mm, which is made of hot-rolled or cold-rolled silicon steel sheets or iron-nickel sheets. The punching sheet with an outer diameter less than 1m uses a full-circle punching sheet, and the one with an outer diameter greater than 0.99m uses a fan-shaped punching sheet. The ventilation slot sheet is composed of a channel steel and a slot sheet, and one or two channel steels are spot welded on each tooth on the slot sheet. Fastening: The full-circle punching sheet is externally pressed, and the fan-shaped punching sheet is internally pressed.