Different materials for stator and rotor punchings have different performance characteristics

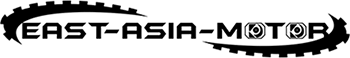

The stator and rotor punching is an important part used in rotating machines such as motors and generators. Its quality and performance directly affect the performance and reliability of the entire machine. Therefore, the production and manufacturing process of the stator and rotor punching is very important.

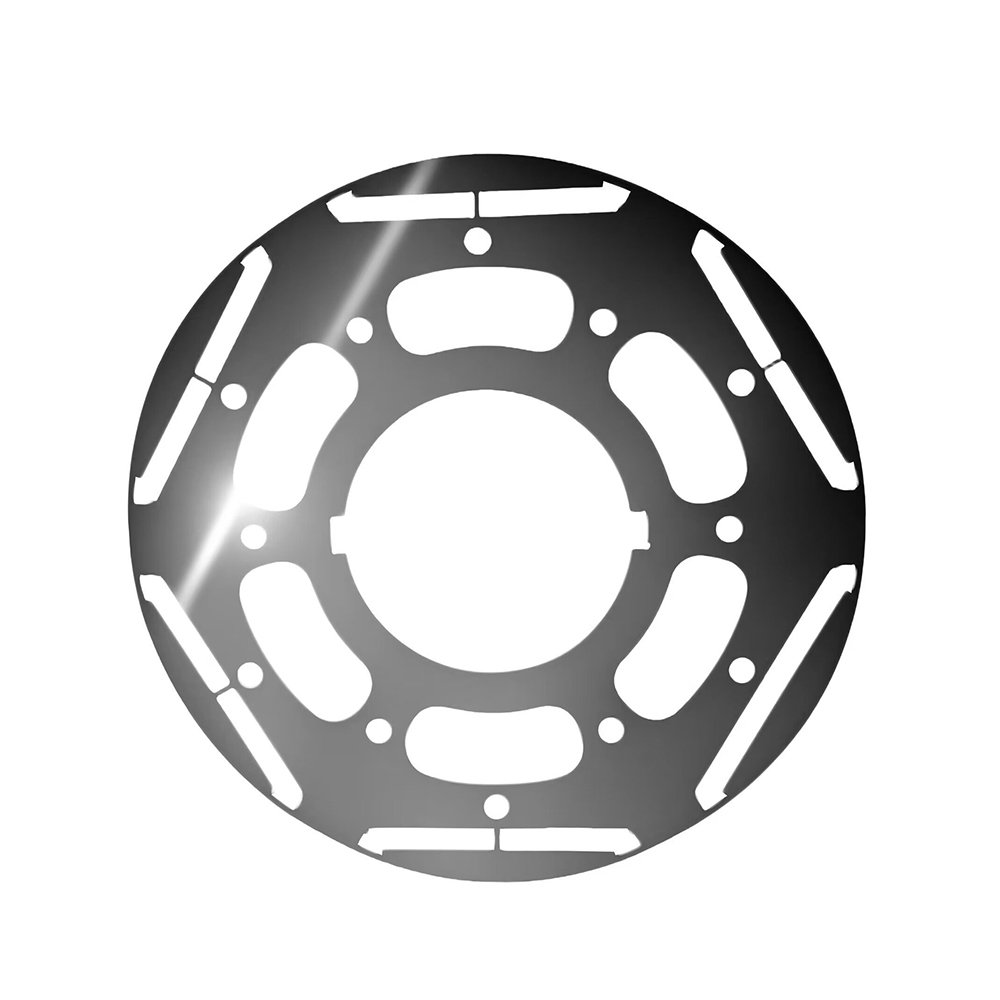

The manufacturing process of the stator and rotor punching includes multiple steps, the most important of which are stamping and lamination. Stamping is the process of stamping the steel plate into the shape of the stator and rotor punching through a die, while lamination is the process of stacking multiple stamped steel plates together to form the stator and rotor. In this process, attention should be paid to precision and quality in each step to ensure the manufacturing quality and performance of the stator and rotor punching.

In addition to the manufacturing process, the selection of materials for the stator and rotor punching also includes steel, stainless steel, aluminum alloy, etc. Different materials have different performance characteristics and need to be selected according to actual needs. At the same time, in order to improve the performance of the stator and rotor punching, the material needs to be heat treated and surface treated.

Stator and rotor inspection personnel need to conduct strict inspections on each batch of non-routine production products, including size, shape, surface quality, performance and other aspects. At the same time, it is also necessary to conduct type tests and factory tests on the products to ensure that the quality and performance of the products meet the requirements.