Zhejiang Yitian Seiko APJ-350 gantry high-speed precision punch press

- Our company uses Zhejiang Yitian Precision APJ-350 gantry high-speed punch press, specializing in ultra-high-efficiency motor core mass production. The equipment punches up to 600 times/minute, with repeated positioning accuracy of ±0.01mm, dynamic vibration <0.03mm, ensuring that the punching burr is ≤0.015mm (better than the national standard G2 level), and the overlap coefficient is ≥98%. With the German servo feeding system, the utilization rate of silicon steel sheets reaches 97%, and the scrap rate is reduced to less than 3%. The IoT system monitors the mold life (more than 5 million punches) and energy consumption (40% energy saving) in real time, and has stably supplied 2 million zero-defect cores to a new energy customer, reducing iron loss by 15% and improving motor energy efficiency by 0.8%. 15-minute fast mold change, 72-hour emergency delivery capability and ±0.5% core weight tolerance meet the stringent requirements of new energy vehicles, industrial servos and home appliances for high-efficiency and low-noise motors. (About 200 words)

- APJ-350 gantry punch press achieves ±0.01mm precision with 600 times/minute high-speed punching, burr ≤0.015mm, and silicon steel utilization rate of 97%. IoT system guarantees mold life of 5 million punches, energy saving of 40%, delivery of 2 million cores with zero defects, iron loss reduction of 15%, and motor energy efficiency improvement of 0.8%. 15-minute mold change, 72-hour emergency response, adapt to new energy, industrial and household appliance motors, weight tolerance ±0.5%, and stacking coefficient ≥98%.

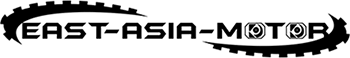

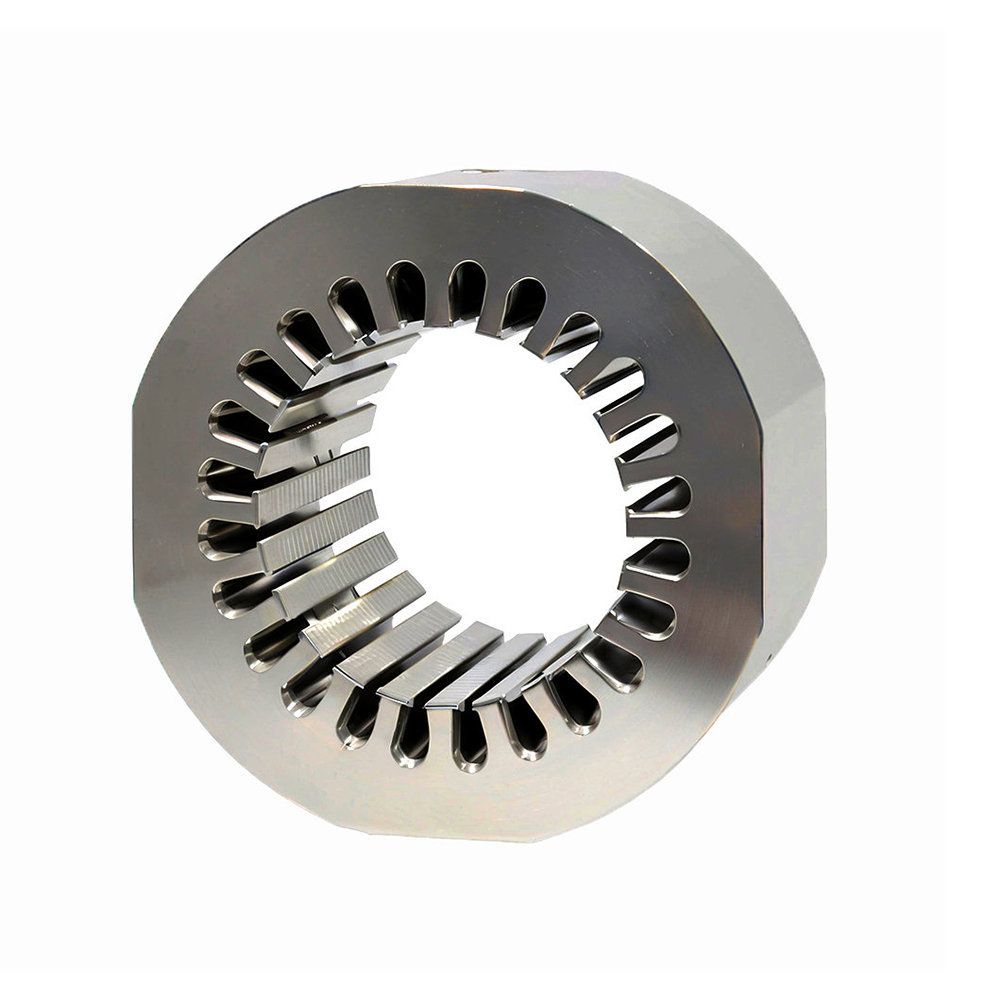

Dongya Motor has been striving to become an industry benchmark over the years. Relying on the core technology of Zhejiang Yitian Seiko APJ-350 gantry high-speed precision punching machine, our stator/rotor punching sheets have reached the industry-leading level in performance, efficiency and reliability. The specific advantages are as follows:

1. High precision · low loss

Using Swiss linear guide closed-loop control technology, the punching sheet contour repetition accuracy is stable within ±0.01mm, the overall axial tolerance of the core after stacking and riveting is ≤0.05mm, and the air gap uniformity is improved by 30%, effectively reducing the motor iron loss and eddy current loss. According to third-party testing, the stacking coefficient of 0.35mm silicon steel sheet core reaches 98.2%, which is 15% lower than the traditional process iron loss, helping customers achieve the IE5 ultra-high efficiency motor energy efficiency goal.

2. Zero burr & no rework

The patented dynamic balancing system controls the punching vibration (amplitude <0.03mm), and with the die gap adaptive compensation technology, the section finish of the punch reaches Ra0.8μm, and the burr height is ≤0.015mm (better than the national standard G2 level standard). It can be directly connected to the fully automatic stacking line, eliminating the cost of secondary deburring and improving production efficiency by more than 20%.

3. High consistency & strong quality control

The equipment is equipped with an IoT intelligent monitoring system to track key parameters such as stamping OEE (≥85%) and die life (≥5 million punches) in real time. With the process capability of CPK≥1.67, it ensures that the weight tolerance of mass-produced cores is ≤±0.5%, and the difference in magnetic flux distribution uniformity is <3%, which completely solves the industry pain points such as abnormal noise and torque fluctuation of motors.

Quick response & cost reduction and efficiency improvement

APJ-350 supports mold switching within 72 hours, with a daily production capacity of over 300,000 punches. Combined with a servo feeding system with a material utilization rate of 97%, the overall cost of a single core piece is reduced by 18%. We have continuously supplied more than 2 million zero-defect core products to a well-known Taiwanese company, with a 100% delivery time achievement rate.

Choose our core products, you will get:

✅ Lower motor comprehensive loss (core efficiency contribution rate increased by 0.8%+)

✅ More stable mass production consistency (customer return rate <0.02‰)

✅ Faster market response speed (urgent order delivery cycle shortened by 50%)

We can provide free core samples and third-party test reports. You are welcome to make an appointment for a factory visit at any time to witness the strength of APJ-350 high-speed stamping technology and quality control system!