OCP-260 Open Type Precision Press

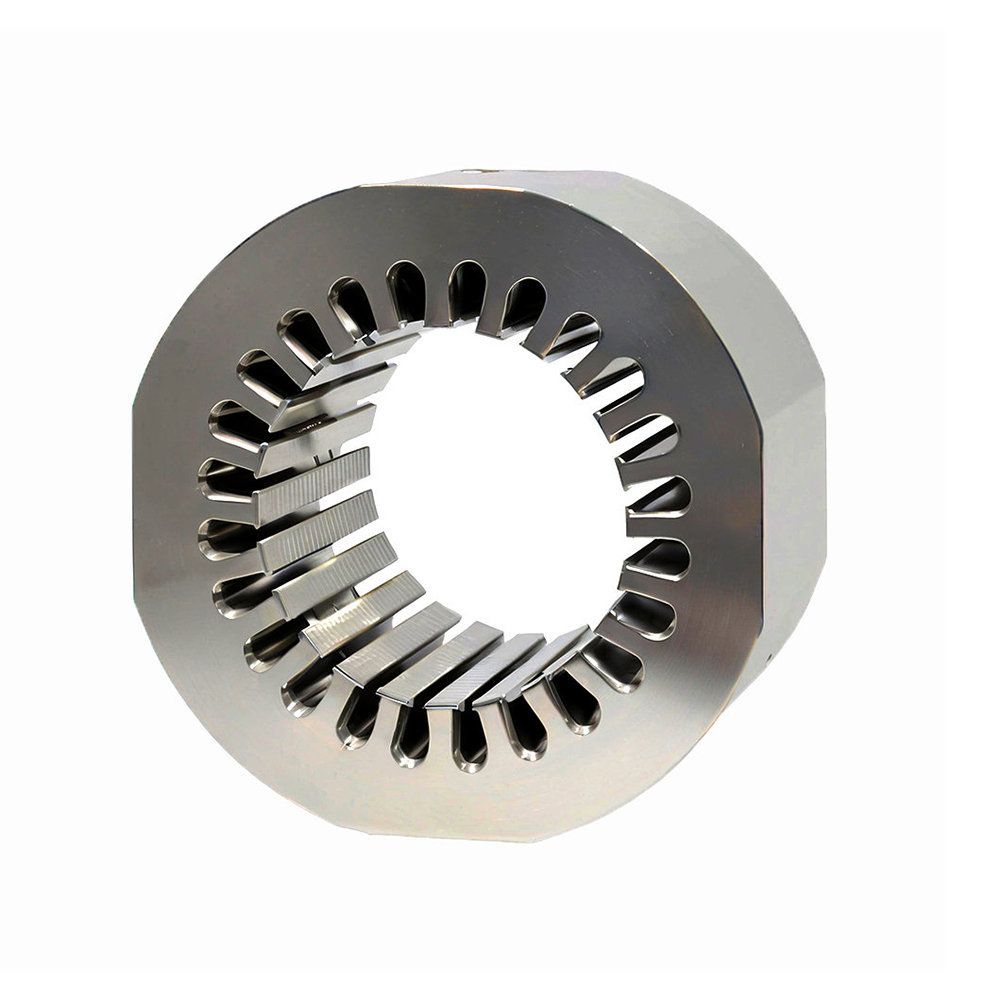

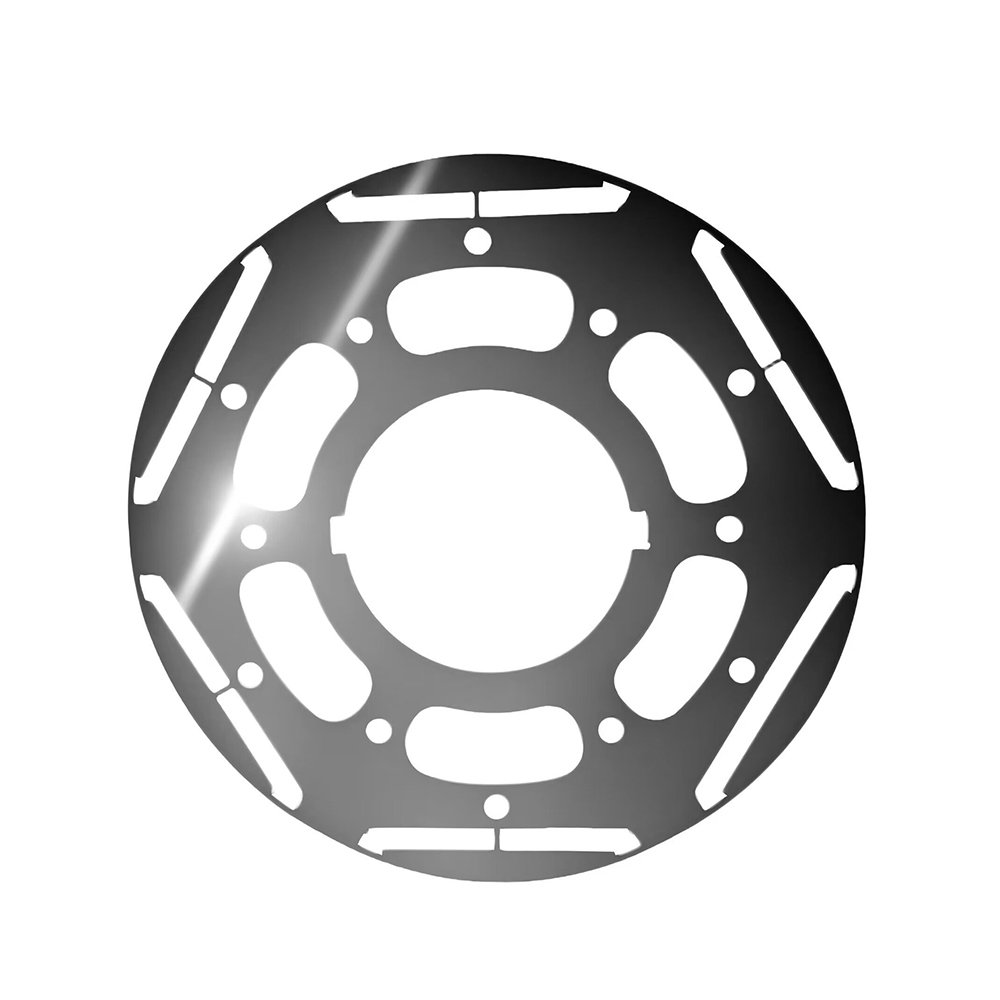

1.OCP-260 is specially designed for 0.35-0.5mm thin motor cores, with a punching rate of 120 times/minute, a repeat positioning accuracy of ±0.06mm, burrs ≤0.04mm after manual adjustment, and a stacking coefficient ≥0.94. It is suitable for cores with an outer diameter of 80-300mm, a material utilization rate of 90%, and a mold life of more than 1 million punching times (DC53 material). Manual mold change ≤20 minutes, manual sampling pass rate ≥97%, and a unit cost of 0.12 yuan/piece, meeting the IE3 energy efficiency requirements of home appliances and industrial motors, 96-hour delivery, and a cost-effective benchmark for mid-range models.

2. OCP-260 core advantages

(1). Precision blanking of thin materials:

0.35mm silicon steel sheet burr ≤0.04mm (≤0.02mm after vibration deburring), dimensional tolerance ±0.06mm, overlap coefficient ≥0.94;

0.5mm cold-rolled plate flatness ≤0.1mm/100mm, dynamic balancing pass rate ≥98% after manual sorting.

(2). Process adaptability:

Full coverage of 80-300mm outer diameter iron core, standard DC53 high-life mold (cost 50,000-80,000 yuan/set), material utilization rate 90%;

Manual mold change ≤20 minutes (guide column mold frame), manual sampling of 3 pieces per hour, full inspection of key dimensions.

(3). Economical and efficient mass production:

Punching speed 120 times/minute, single-shift capacity 5000-6000 pieces, single-piece processing fee 0.12 yuan, 50% lower than servo punching machine;

Compatible with silicon steel, amorphous alloy (0.35-1.0mm), suitable for IE3 energy-efficient motors and new energy auxiliary drive cores.

Restriction description:

Not suitable for precision scenes with outer diameter > 300mm or burr requirements ≤ 0.015mm;

(Note: The parameters are based on "GB/T 13914-2013" and industry measured data, focusing on the cost-effectiveness of thin materials and highlighting the ability of manual fine control.)