SJF/DLT series synchronous leveling machine double-end material equipment

1. Synchronous control of double-head materials: Independent servo drive for double stations, leveling speed matches punching times (up to 60m/min), material strip spacing accuracy ±0.1mm, supports dual-material asynchronous/synchronous feeding mode, material change without stopping, and efficiency increased by 40%.

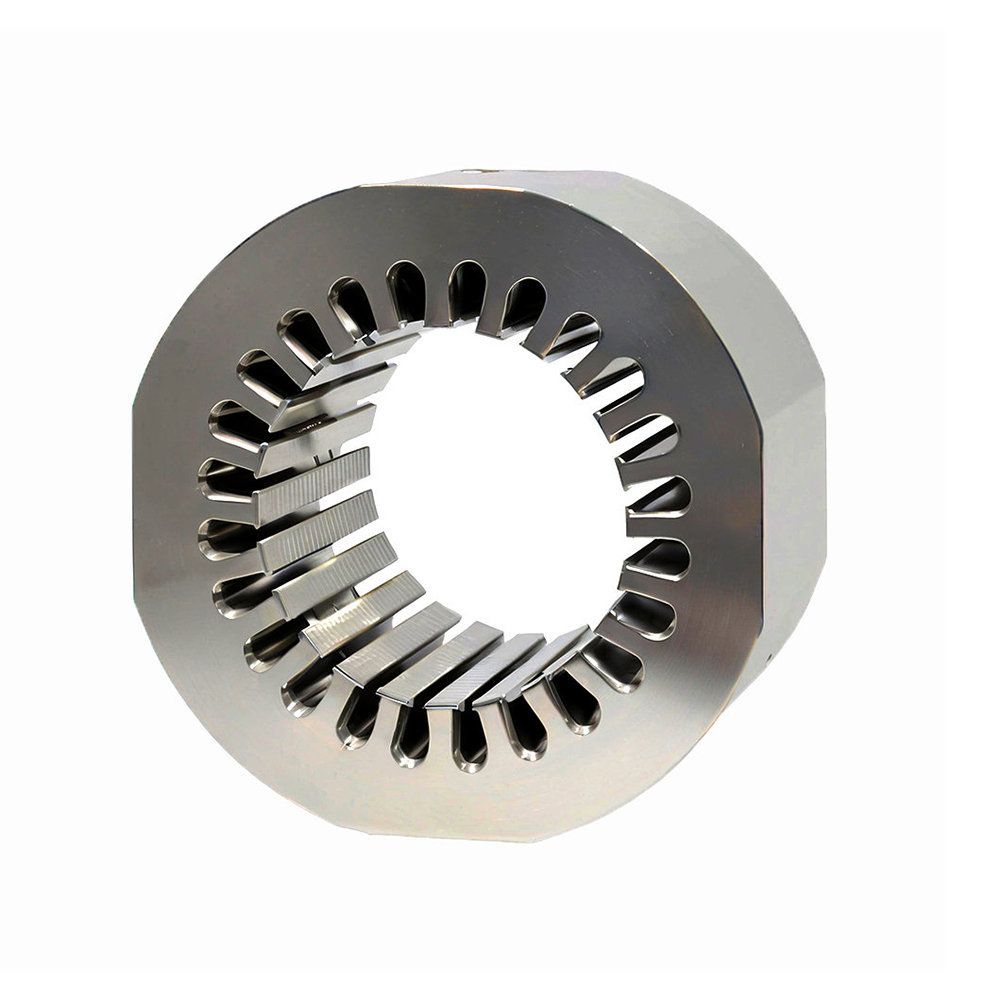

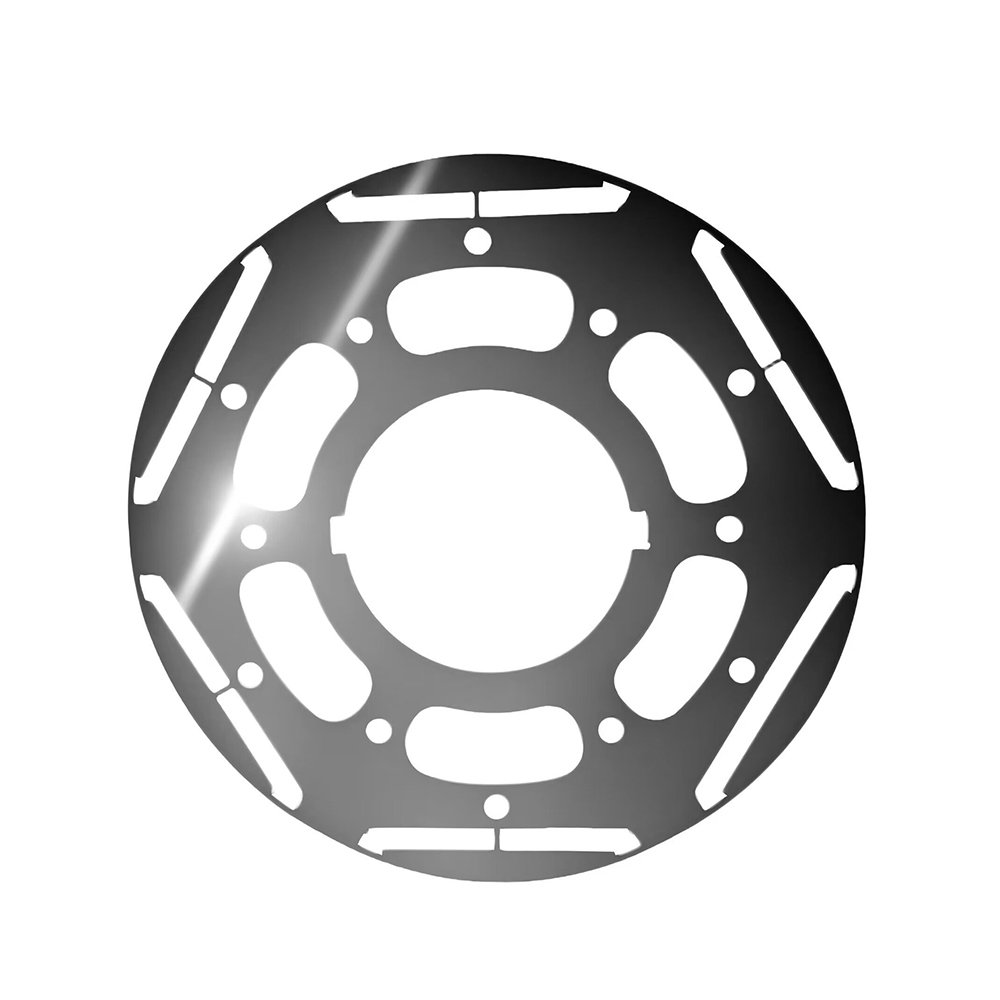

High-precision leveling of ultra-thin sheets: Multi-roller precision straightening technology (12-20 rollers) is adopted, the flatness after leveling is ≤0.02mm/m, the internal stress of the material is eliminated, the punching burr is ensured to be ≤0.015mm, and the stacking coefficient is increased to more than 98%.

Intelligent linkage system: Real-time communication with the punch PLC, automatic compensation for material elongation fluctuations (±0.05%), independent closed-loop control of dual-material tension, alarm and shutdown within 0.5 seconds of material breakage/material deviation, and the scrap rate is reduced to less than 0.1%.

Quick changeover compatibility: The SJF series supports 50-350mm material width, and the DLT series supports independent width adjustment of double materials (50-200mm/strip). The changeover time is ≤10 minutes, which is suitable for efficient production scenarios such as double-row punching of new energy flat wire motors and multi-station progressive dies for home appliances.

2. Dual servo independent material control: Leveling speed 60m/min, spacing accuracy ±0.1mm;

Multi-roller precision leveling: Flatness ≤0.02mm/m, burr ≤0.015mm;

Intelligent linkage error prevention: 0.5 seconds alarm for material breakage, scrap rate <0.1%;

Quick changeover: Switch material width (50-350mm) in 10 minutes, suitable for efficient production of double-row punching and progressive dies.