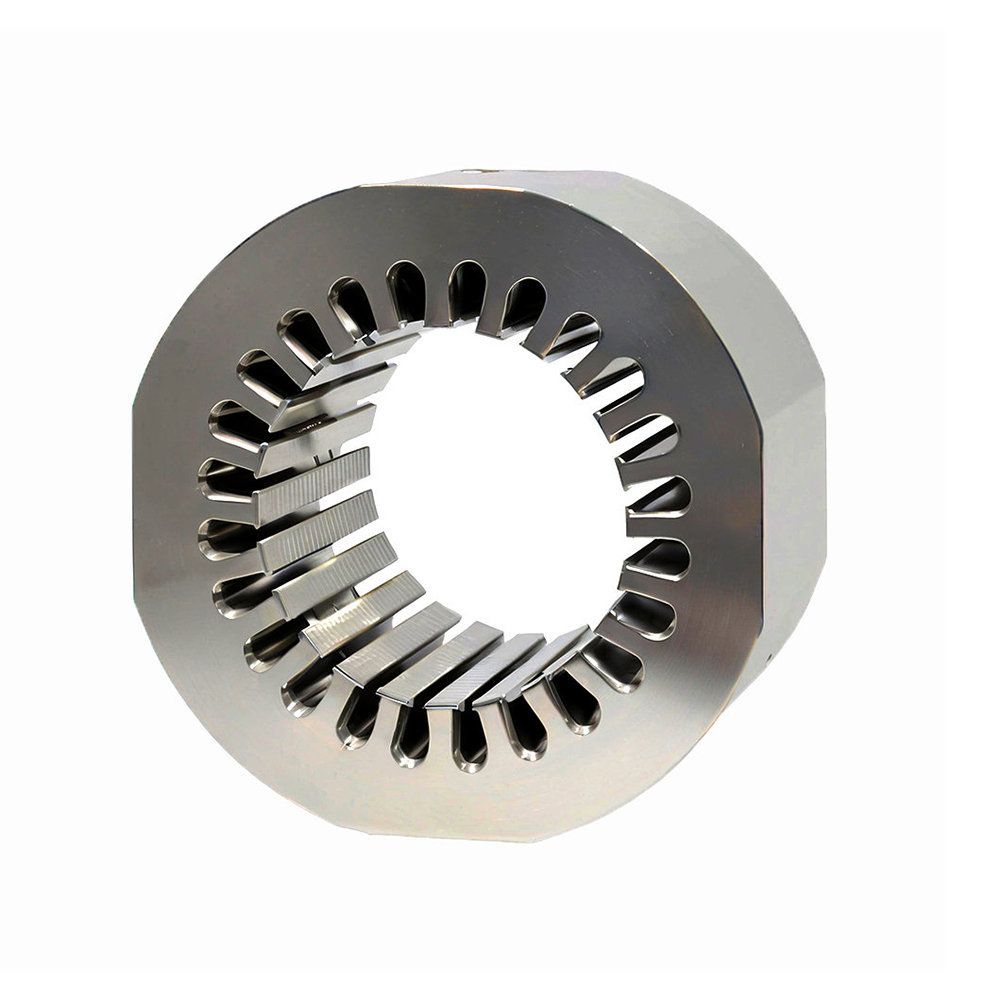

CCS (SF2)-100/160, servo driven high speed notching machine series

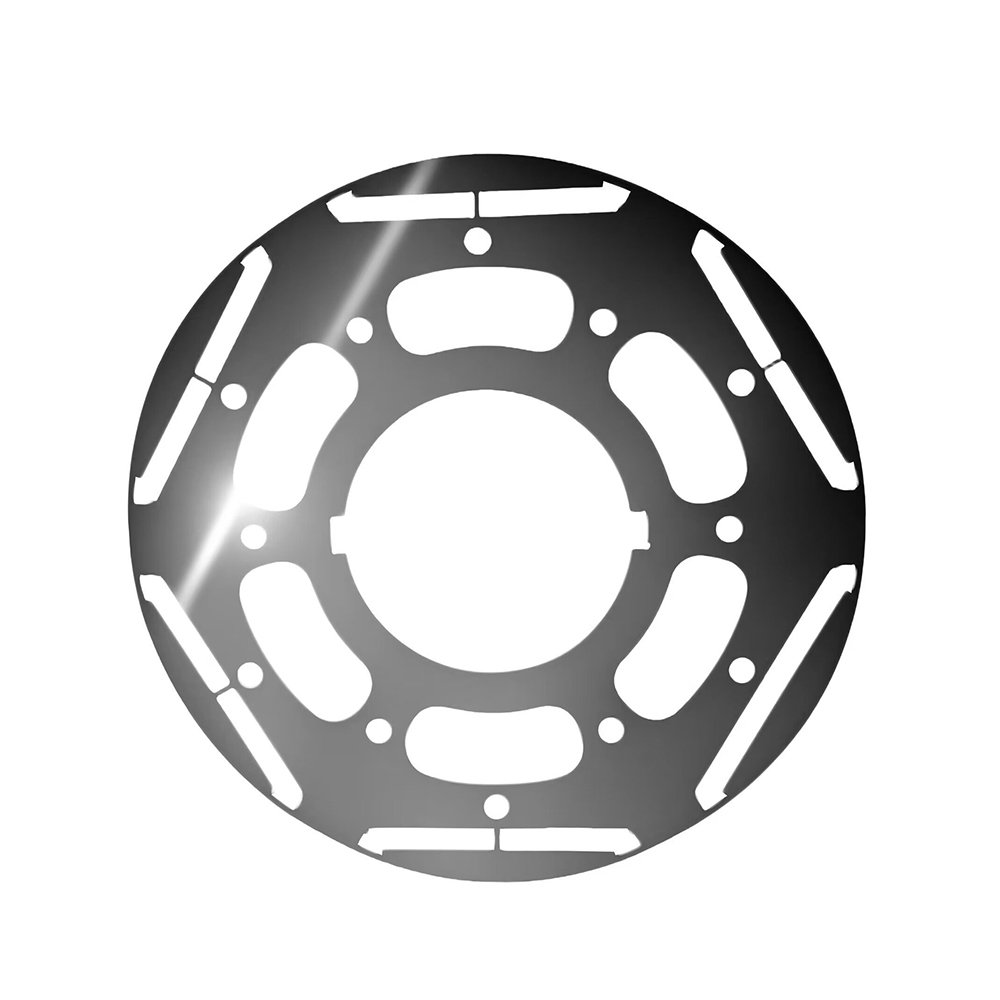

1. CCS series full servo slot punching machine is deeply engaged in 0.35/0.5mm silicon steel sheet processing:

100 type: 100 tons of pressure, ±0.01mm slot width accuracy, small slot is efficient and stable;160 type: Five-axis linkage slot control, ±0.005mm accuracy, all-round for new energy flat wire/IPM slot.

The burr of the whole series is ≤0.015mm, the mold life is 6 million punches, the manual mold change accuracy is ±0.003mm, the material utilization rate is 97%, and it is suitable for mass production of ultra-high efficiency motor cores.

2. CCS-100: Specializes in the field of small motors, 100 tons of punch force is suitable for 0.35-0.5mm silicon steel sheets, slot width 0.5-5mm, accuracy ±0.01mm, burr ≤0.015mm, manual mold change process is standardized, mold life exceeds 6 million punches, and material utilization rate reaches 97%.

CCS-160: Focuses on new energy and industrial servo motors, the five-axis linkage servo system accurately controls V-type/IPM/flat wire slots, slot width ±0.005mm, punches 400 times/minute (0.5mm material), slot depth fluctuation ≤0.002mm, burrs ≤0.01mm, meeting the stringent requirements of ultra-high efficiency motor slots.

The entire series is equipped with split die frame vibration suppression technology as standard. The repeat positioning accuracy after manual die change is ±0.003mm. The localized data system tracks the blanking angle and pressure in real time to ensure CPK≥1.67, providing an industry benchmark processing solution for 0.35/0.5mm silicon steel sheets.