What Are the Different Types of Electric Motors and Their Key Characteristics

Electric motors are categorized into AC, DC, and special purpose types, each with unique attributes suited to specific applications. AC motors, known for durability and stable operation, dominate industrial and household uses, with variants like synchronous and induction motors offering distinct advantages in efficiency and control. DC motors provide high torque and precise speed regulation, ideal for robotics, automotive, and automation tasks. Special purpose motors, including stepper and servo models, prioritize accuracy and advanced control, essential for cutting-edge automation and robotics. Selecting the appropriate motor hinges on load demands, environmental conditions, and performance goals, ensuring optimal efficiency and longevity.

Electric motors types fall into three main categories: AC motors, DC motors, and special purpose motors. Each type serves unique functions and features that suit specific electric motor applications. AC motors dominate the market because of their durability and stable speed, while DC motors excel in efficiency and compact design. Special purpose motors offer precise control for tasks such as robotics or automation.

| Electric Motors Types | Distinctive Characteristics | Common Uses |

| AC Motors | Durable, low maintenance, stable speed | Industry, homes, offices |

| DC Motors | Efficient, compact, high torque at low speed | Electronics, automotive |

| Special Purpose Motors | Precision, unique traits | Robotics, automation, HVAC |

Key Takeaways

AC motors offer durability and low maintenance, making them ideal for continuous industrial and household use.

DC motors provide high efficiency and precise speed control, perfect for applications needing rapid response and high torque.

Special purpose motors deliver advanced control and accuracy, essential for robotics, automation, and precision tasks.

Synchronous AC motors run at constant speed with high efficiency, while induction motors are simpler and more versatile but less precise.

Choosing the right motor type depends on the load, speed, control needs, and environment to ensure reliable and cost-effective performance.

Electric Motors Types Overview

Quick Comparison

Electric motors types fall into three primary categories: AC motors, DC motors, and special purpose motors. Each category offers distinctive characteristics that suit specific electric motor applications. AC motors provide durability and stable speed, making them ideal for continuous operation in industrial and household settings. DC motors deliver high efficiency and rapid response, which benefits machinery requiring constant power or quick acceleration. Special purpose motors, such as servomotors, enable precise control of position and speed through advanced feedback systems. These motors are essential in robotics, CNC machinery, and automation where accuracy and repeatability matter.

Tip: Choosing the right motor type depends on the required performance, control, and application environment.

| Motor Type | Efficiency & Performance | Cost & Maintenance | Typical Applications |

| AC Motors | Powerful, durable, stable speed | Low maintenance, long life | Appliances, conveyors, fans, pumps |

| DC Motors | High efficiency, fast response | Low initial cost, more upkeep with size | Production units, elevators, warehouse equipment |

| Special Purpose | Precise control, advanced feedback | Higher cost, complex | Robotics, CNC machinery, automation |

Key Differences

AC motors stand out for their robust construction and compatibility with variable frequency drives, which allow flexible speed and torque control. They require less maintenance due to the absence of brushes and suit multi-phase configurations. DC motors excel in energy efficiency and provide high startup torque, making them suitable for equipment that demands quick acceleration. Brushed DC motors offer a low-cost solution but need frequent maintenance, while brushless DC motors deliver better efficiency and longer lifespan at a higher price.

Special purpose motors, including servomotors, combine brushless or AC induction motors with controllers and sensors. These motors achieve high accuracy and repeatability, but their complexity leads to increased costs. In demanding industrial settings, inverter-rated AC motors replace standard DC drives, offering extended speed ranges and enhanced overload capacity. Power-dense designs and thermal protection make these motors suitable for variable-speed applications.

The types of electric motors differ in efficiency, cost, and application suitability. AC motors dominate environments needing durability and stable operation. DC motors serve best where efficiency and rapid response are priorities. Special purpose motors address tasks requiring precision and advanced control.

Types of AC Motors

Synchronous Motors

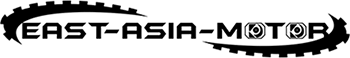

Synchronous motors represent a major category within ac motors. These motors operate with the rotor speed matching the speed of the stator's magnetic field. This feature eliminates slip and ensures precise speed control. Synchronous ac motors use either permanent magnets or external excitation to lock the rotor and stator fields together. The result is high energy efficiency and constant speed, regardless of load changes.

| Aspect | Synchronous Motor (Permanent Magnet) |

| Rotor Speed | Matches stator magnetic field speed exactly (no slip) |

| Torque Production | Rotor is magnetically locked with stator field, no induced current |

| Energy Efficiency | Higher efficiency due to no slip losses and permanent magnets |

| Speed Control | Precise and constant speed regardless of load |

| Excitation | Uses permanent magnets or external excitation (DC supply) |

| Cost and Maintenance | Higher upfront cost; less day-to-day maintenance but complex installation |

| Suitability | Ideal for applications requiring precise speed and high efficiency |

Synchronous motors excel in electric motor applications that demand constant speed and high accuracy. They often appear in generators, precision equipment, and synchronous speed control drives. Industrial settings rely on synchronous ac motors for large pumps, compressors, conveyor systems, and power factor correction in electrical grids. These motors deliver reliable performance where speed stability is critical.

Note: Synchronous ac motors require complex installation and higher initial investment, but they offer reduced maintenance over time.

Induction (Asynchronous) Motors

Induction motors, also known as asynchronous motors, dominate the market for ac motors due to their rugged design and versatility. Unlike synchronous motors, induction motors operate with rotor speed lagging behind the stator's magnetic field speed. This difference, called slip, induces current in the rotor and produces torque. Asynchronous motor operation leads to some energy loss, but the design remains simple and cost-effective.

| Aspect | Induction Motor (Asynchronous) |

| Rotor Speed | Rotor speed lags behind stator magnetic field (slip present) |

| Torque Production | Slip induces current in rotor to produce torque |

| Energy Efficiency | Less efficient due to slip causing energy losses |

| Speed Control | Speed varies slightly with load due to slip |

| Excitation | No external excitation needed; relies on electromagnetic induction |

| Cost and Maintenance | Lower initial cost; simpler design and maintenance |

| Suitability | Suitable for robust, general-purpose power with variable loads |

Induction motors provide reliable service in compressors, pumps, fans, electric locomotives, and factory automation. Asynchronous motor technology supports high-power drive equipment and industrial machinery. These motors also power HVAC systems, conveyor belts, and household appliances. Their simple construction and low maintenance requirements make them a popular choice for general-purpose electric motor applications.

Tip: Induction motors offer flexibility for variable loads and environments where durability matters more than precision.

AC Motor Subtypes

Ac motors include several subtypes designed for specific starting and operating conditions. Each subtype offers distinctive characteristics in terms of starting torque and energy consumption.

| Motor Type | Starting Torque | Energy Consumption / Efficiency |

| Shaded Pole | Low starting torque | Low efficiency (~30%), suitable for low-demand loads |

| Split Phase | Low starting torque, high starting current | Moderate efficiency, suitable for low torque needs |

| Capacitor Start | High starting torque (up to 4x normal) | Relatively low operating efficiency, higher energy use at startup |

| Permanent Split Capacitor (PSC) | Low starting torque | Better efficiency than shaded pole, low starting current |

Shaded-pole motors: These asynchronous motors provide low starting torque and low efficiency. They suit small fans and appliances with minimal load.

Split-phase motors: These asynchronous motors deliver moderate efficiency and low starting torque. They work well in low-torque applications such as washing machines.

Capacitor-start motors: These asynchronous motors generate high starting torque, making them ideal for compressors and pumps. They consume more energy during startup.

Permanent split capacitor (PSC) motors: These asynchronous motors balance efficiency and low starting current. They serve in HVAC blowers and fans.

Note: Brushless electric motor technology, often called BLDC, falls under ac motors. BLDC motors use electronic controllers for precise speed and torque control. They offer high efficiency, low noise, and long lifespan. However, they require complex control systems and have higher initial costs compared to traditional ac motors.

Ac motors, including synchronous motors, induction motors, and their subtypes, provide solutions for a wide range of electric motor applications. Synchronous ac motors deliver precision and efficiency, while asynchronous motor designs offer durability and simplicity. The choice of motor subtype depends on the required starting torque, efficiency, and application environment.

Types of DC Motors

DC motors play a vital role in modern industry and consumer products. Engineers select from several types of dc motors based on performance requirements, control needs, and application environments. Each type offers distinctive characteristics that influence speed regulation, torque output, and suitability for specific electric motor applications.

Series DC Motors

Series DC motors feature a field winding connected in series with the armature. This design causes the field current to equal the armature current, resulting in very high starting torque. The torque output increases rapidly as the armature current rises, making these motors ideal for heavy-duty tasks. However, speed varies widely with load. At no load, the speed can increase dangerously, so operators must always connect a load to prevent overspeed.

| Parameter | Series DC Motor |

| Field Winding Connection | Series with armature |

| Starting Torque | Very high |

| Speed Regulation | Poor; speed varies widely with load |

| Typical Applications | Cranes, hoists, locomotives, electric bikes and cars |

Series dc motors excel in applications requiring high starting torque, such as cranes and elevators. Their dynamic response suits tasks with frequent starts and stops. However, they do not perform well in constant speed operations or variable speed drives.

⚡ Tip: Always ensure a load is connected to a series DC motor to avoid overspeed and potential damage.

Shunt DC Motors

Shunt DC motors use a field winding connected in parallel (shunt) with the armature. The field current remains independent from the armature current, which allows for better speed regulation. These motors maintain nearly constant speed under varying loads, although speed decreases slightly as load increases. Shunt dc motors require careful starting under heavy loads due to the need for large starting current.

| Parameter | Shunt DC Motor |

| Field Winding Connection | Parallel (shunt) with armature |

| Starting Torque | Low and constant |

| Speed Regulation | Good; speed remains nearly constant |

| Typical Applications | Fans, blowers, elevators, centrifugal pumps, lathes |

Shunt dc motors suit applications where constant speed is essential, such as fans and pumps. Their simplified reversing control and ability to support regenerative drives make them popular in industrial settings.

Note: Shunt dc motors provide reliable performance in electric motor applications that demand steady speed and moderate torque.

Compound DC Motors

Compound DC motors combine the features of series and shunt dc motors by incorporating both series and shunt field windings. This design delivers high starting torque from the series field and good speed regulation from the shunt field. Compound dc motors balance these traits, offering versatile performance for varying load conditions.

| Parameter | Compound DC Motor |

| Field Winding Connection | Combination of series and shunt |

| Starting Torque | High (not as high as pure series) |

| Speed Regulation | Moderate to good |

| Typical Applications | Heavy-duty gear, automotive starters, variable load |

Compound dc motors adapt well to industrial gear systems and automotive starters. Their robust torque characteristics and adaptability make them suitable for electric motor applications with fluctuating loads. Operators can adjust winding configurations to optimize performance, although these motors may require increased maintenance.

⚙️ Compound dc motors offer a practical solution when both high starting torque and effective speed regulation are needed.

Permanent Magnet DC Motors

Permanent magnet DC motors use permanent magnets to supply field flux, eliminating the need for field windings. This design reduces size and cost, especially for small ratings. Permanent magnet dc motors deliver excellent starting torque and good speed regulation. However, torque remains limited to prevent demagnetization of the magnets.

| Feature/Aspect | Permanent Magnet DC Motor |

| Field Flux | Provided by permanent magnets |

| Starting Torque | High |

| Speed Regulation | Good; speed controlled by armature voltage |

| Efficiency | High; no field copper losses |

| Size and Weight | Compact, lightweight |

| Typical Applications | Electric toothbrushes, vacuum cleaners, toys, automotive components |

Permanent magnet dc motors excel in small, low-power electric motor applications. Their compact and lightweight design suits portable tools and household devices. Engineers use rare-earth magnets to enhance performance in size-sensitive and high-performance products. These motors operate efficiently, quietly, and require minimal maintenance.

Permanent magnet dc motors provide a consistent magnetic field without energy input.

They offer improved performance and operate over wide temperature ranges.

Common uses include computer drives, automotive components, and smart appliances.

Permanent magnet dc motors power electric vehicles, praised for their efficiency and cost optimization.

DC Motor Comparison Table

| Motor Type | Construction/Field Connection | Speed Regulation | Torque Output Characteristics | Typical Applications |

| Series DC Motor | Field winding in series with armature | Poor; speed varies widely with load | Very high starting torque; speed varies with load | Cranes, hoists, locomotives, electric bikes and cars |

| Shunt DC Motor | Field winding in parallel (shunt) | Good; nearly constant speed | Low and constant starting torque; torque increases with speed | Fans, blowers, elevators, centrifugal pumps, lathes |

| Compound DC Motor | Combination of series and shunt fields | Moderate to good | High starting torque; balanced speed regulation | Heavy-duty gear, automotive starters, variable load |

| Permanent Magnet DC | Uses permanent magnets for field flux | Good; speed controlled by armature voltage | High starting torque; limited load capacity | Electric toothbrushes, vacuum cleaners, toys, automotive components |

DC motors offer engineers a range of options for electric motor applications. Series dc motors deliver powerful starts for heavy loads. Shunt dc motors maintain steady speed for fans and pumps. Compound dc motors balance torque and speed regulation for versatile tasks. Permanent magnet dc motors provide efficient, compact solutions for small devices and automotive components.

Different Types of Special Purpose Motors

Special motors serve electric motor applications that demand precision, unique control, or adaptability. These motors often operate under demanding duty cycles, which involve repeated phases of starting, running, and braking. Proper thermal management becomes essential, as frequent cycling can raise temperatures and affect longevity. Selecting the right special motors ensures reliable performance and extends service life.

Stepper Motors

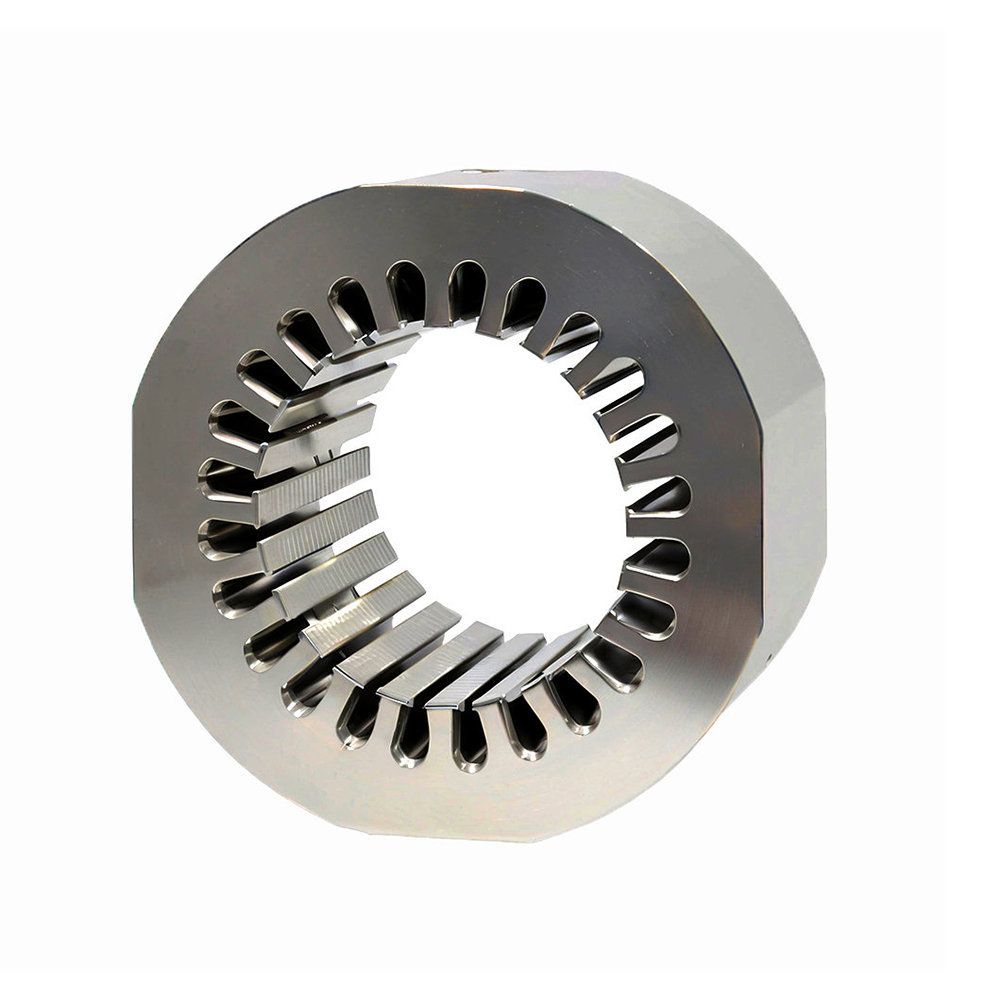

Stepper motors move in precise, discrete steps, making them ideal for applications that require accurate positioning. Each step represents a fixed angle, such as 1.8°, allowing for high-resolution control. Stepper motors use different rotor types: permanent magnet, variable reluctance, and hybrid. Permanent magnet rotors offer good holding torque, while variable reluctance rotors provide higher speed and resolution. Hybrid rotors combine both features for superior performance. Stepper motors operate in open-loop systems, so they do not need feedback devices. However, they can lose position if overloaded or run at high speeds. These special motors excel in 3D printers, CNC machines, and camera platforms.

Stepper motors deliver reliable, cost-effective motion control but may stall or lose accuracy under heavy loads.

Servo Motors

Servo motors provide precise control of position, speed, and torque through closed-loop feedback systems. They use encoders or resolvers to monitor movement and adjust in real time. This feedback enables servo motors to maintain accuracy even when loads change. Their construction includes rare earth magnets and high torque density, supporting dynamic and high-speed operations. Servo motors suit robotics, automation, and conveyor systems where repeatability and adaptability are critical. Although more complex and costly than stepper motors, servo motors offer superior performance for demanding tasks.

| Characteristic | Stepper Motor (Open-Loop) | Servo Motor (Closed-Loop) |

| Feedback | None | Continuous (encoder/resolver) |

| Position Accuracy | Assumed by step count | Measured and corrected in real time |

| Load Adaptability | Limited | High |

| System Complexity | Low | High |

| Cost | Lower | Higher |

Universal Motors

Universal motors operate on both AC and DC power supplies. Their series-wound design delivers high starting torque and speeds above 3500 rpm. These special motors perform well in portable tools, household appliances, and devices that require compact size and variable speed. Universal motors can run at high speeds on AC and maintain similar performance on DC at equivalent voltages. Their versatility makes them a popular choice for blenders, drills, and vacuum cleaners.

Universal motors combine flexibility with powerful performance, making them suitable for many consumer products.

Synchronous Reluctance Motors

Synchronous reluctance motors feature a cage-type rotor and auxiliary windings, similar to induction motors. These special motors synchronize with the supply frequency, providing stable speed and efficient operation. Synchronous reluctance motors find use in lifts, wind turbines, and traction systems for railways and industrial vehicles. Their robust design supports gearless drives and renewable energy projects. Engineers value these motors for their reliability and ability to handle demanding duty cycles.

Synchronous reluctance motors support applications that require synchronization and efficient energy use.

They play a key role in modern transportation and renewable energy sectors.

Selecting the right electric motor depends on understanding the distinctive characteristics of each type. AC motors offer durability and low maintenance, making them ideal for continuous industrial use. DC motors provide precise speed and torque control, which suits applications needing rapid response. Special motors deliver advanced control for tasks like robotics. The table below highlights key selection factors:

| Factor | DC Motor Characteristics | AC Motor Characteristics |

| Power Source | Uses direct current (battery or rectified supply) | Uses alternating current (grid supply) |

| Speed Control | Excellent, via voltage/current adjustments | Requires variable frequency drive (VFD) or inverter |

| Maintenance | Higher due to brushes and commutators | Lower, brushless and simpler design |

For electric motor applications, matching motor type to load, speed, and environment ensures reliable performance and cost efficiency.

FAQ

What are the main electric motors types used in industry?

Industry often uses ac motors, dc motors, and special motors. Each type offers distinctive characteristics. Ac induction motors provide durability. Dc motors deliver high torque. Special motors support precision tasks. Selection depends on electric motor applications and performance needs.

How do synchronous motors differ from induction motors?

Synchronous motors operate at a constant speed matching the supply frequency. Induction motors, also called asynchronous motor types, run slightly slower due to slip. Synchronous ac motors suit precise speed control. Ac induction motors work well in general-purpose electric motor applications.

Where are brushless electric motor designs most effective?

Brushless electric motor designs excel in applications needing high efficiency and low maintenance. These motors appear in robotics, electric vehicles, and HVAC systems. Their advanced controllers provide precise speed and torque, making them ideal for modern electric motor applications.

What are the distinctive characteristics of special motors?

Special motors offer unique features such as stepwise movement, feedback control, or compatibility with both AC and DC power. These distinctive characteristics make them essential for robotics, automation, and other electric motor applications requiring accuracy and adaptability.

Why choose different types of electric motors for specific tasks?

Engineers select different types of electric motors based on load, speed, and control requirements. Ac motors handle continuous operation. Dc motors provide rapid response. Special motors deliver advanced control. Matching motor type to application ensures optimal performance and reliability.

Electric motors are categorized into AC, DC, and special purpose types, each with unique attributes suited to specific applications. AC motors, known for durability and stable operation, dominate industrial and household uses, with variants like synchronous and induction motors offering distinct advantages in efficiency and control. DC motors provide high torque and precise speed regulation, ideal for robotics, automotive, and automation tasks. Special purpose motors, including stepper and servo models, prioritize accuracy and advanced control, essential for cutting-edge automation and robotics. Selecting the appropriate motor hinges on load demands, environmental conditions, and performance goals, ensuring optimal efficiency and longevity.

Electric motors types fall into three main categories: AC motors, DC motors, and special purpose motors. Each type serves unique functions and features that suit specific electric motor applications. AC motors dominate the market because of their durability and stable speed, while DC motors excel in efficiency and compact design. Special purpose motors offer precise control for tasks such as robotics or automation.

| Electric Motors Types | Distinctive Characteristics | Common Uses |

| AC Motors | Durable, low maintenance, stable speed | Industry, homes, offices |

| DC Motors | Efficient, compact, high torque at low speed | Electronics, automotive |

| Special Purpose Motors | Precision, unique traits | Robotics, automation, HVAC |

Key Takeaways

AC motors offer durability and low maintenance, making them ideal for continuous industrial and household use.

DC motors provide high efficiency and precise speed control, perfect for applications needing rapid response and high torque.

Special purpose motors deliver advanced control and accuracy, essential for robotics, automation, and precision tasks.

Synchronous AC motors run at constant speed with high efficiency, while induction motors are simpler and more versatile but less precise.

Choosing the right motor type depends on the load, speed, control needs, and environment to ensure reliable and cost-effective performance.

Electric Motors Types Overview

Quick Comparison

Electric motors types fall into three primary categories: AC motors, DC motors, and special purpose motors. Each category offers distinctive characteristics that suit specific electric motor applications. AC motors provide durability and stable speed, making them ideal for continuous operation in industrial and household settings. DC motors deliver high efficiency and rapid response, which benefits machinery requiring constant power or quick acceleration. Special purpose motors, such as servomotors, enable precise control of position and speed through advanced feedback systems. These motors are essential in robotics, CNC machinery, and automation where accuracy and repeatability matter.

Tip: Choosing the right motor type depends on the required performance, control, and application environment.

| Motor Type | Efficiency & Performance | Cost & Maintenance | Typical Applications |

| AC Motors | Powerful, durable, stable speed | Low maintenance, long life | Appliances, conveyors, fans, pumps |

| DC Motors | High efficiency, fast response | Low initial cost, more upkeep with size | Production units, elevators, warehouse equipment |

| Special Purpose | Precise control, advanced feedback | Higher cost, complex | Robotics, CNC machinery, automation |

Key Differences

AC motors stand out for their robust construction and compatibility with variable frequency drives, which allow flexible speed and torque control. They require less maintenance due to the absence of brushes and suit multi-phase configurations. DC motors excel in energy efficiency and provide high startup torque, making them suitable for equipment that demands quick acceleration. Brushed DC motors offer a low-cost solution but need frequent maintenance, while brushless DC motors deliver better efficiency and longer lifespan at a higher price.

Special purpose motors, including servomotors, combine brushless or AC induction motors with controllers and sensors. These motors achieve high accuracy and repeatability, but their complexity leads to increased costs. In demanding industrial settings, inverter-rated AC motors replace standard DC drives, offering extended speed ranges and enhanced overload capacity. Power-dense designs and thermal protection make these motors suitable for variable-speed applications.

The types of electric motors differ in efficiency, cost, and application suitability. AC motors dominate environments needing durability and stable operation. DC motors serve best where efficiency and rapid response are priorities. Special purpose motors address tasks requiring precision and advanced control.

Types of AC Motors

Synchronous Motors

Synchronous motors represent a major category within ac motors. These motors operate with the rotor speed matching the speed of the stator's magnetic field. This feature eliminates slip and ensures precise speed control. Synchronous ac motors use either permanent magnets or external excitation to lock the rotor and stator fields together. The result is high energy efficiency and constant speed, regardless of load changes.

| Aspect | Synchronous Motor (Permanent Magnet) |

| Rotor Speed | Matches stator magnetic field speed exactly (no slip) |

| Torque Production | Rotor is magnetically locked with stator field, no induced current |

| Energy Efficiency | Higher efficiency due to no slip losses and permanent magnets |

| Speed Control | Precise and constant speed regardless of load |

| Excitation | Uses permanent magnets or external excitation (DC supply) |

| Cost and Maintenance | Higher upfront cost; less day-to-day maintenance but complex installation |

| Suitability | Ideal for applications requiring precise speed and high efficiency |

Synchronous motors excel in electric motor applications that demand constant speed and high accuracy. They often appear in generators, precision equipment, and synchronous speed control drives. Industrial settings rely on synchronous ac motors for large pumps, compressors, conveyor systems, and power factor correction in electrical grids. These motors deliver reliable performance where speed stability is critical.

Note: Synchronous ac motors require complex installation and higher initial investment, but they offer reduced maintenance over time.

Induction (Asynchronous) Motors

Induction motors, also known as asynchronous motors, dominate the market for ac motors due to their rugged design and versatility. Unlike synchronous motors, induction motors operate with rotor speed lagging behind the stator's magnetic field speed. This difference, called slip, induces current in the rotor and produces torque. Asynchronous motor operation leads to some energy loss, but the design remains simple and cost-effective.

| Aspect | Induction Motor (Asynchronous) |

| Rotor Speed | Rotor speed lags behind stator magnetic field (slip present) |

| Torque Production | Slip induces current in rotor to produce torque |

| Energy Efficiency | Less efficient due to slip causing energy losses |

| Speed Control | Speed varies slightly with load due to slip |

| Excitation | No external excitation needed; relies on electromagnetic induction |

| Cost and Maintenance | Lower initial cost; simpler design and maintenance |

| Suitability | Suitable for robust, general-purpose power with variable loads |

Induction motors provide reliable service in compressors, pumps, fans, electric locomotives, and factory automation. Asynchronous motor technology supports high-power drive equipment and industrial machinery. These motors also power HVAC systems, conveyor belts, and household appliances. Their simple construction and low maintenance requirements make them a popular choice for general-purpose electric motor applications.

Tip: Induction motors offer flexibility for variable loads and environments where durability matters more than precision.

AC Motor Subtypes

Ac motors include several subtypes designed for specific starting and operating conditions. Each subtype offers distinctive characteristics in terms of starting torque and energy consumption.

| Motor Type | Starting Torque | Energy Consumption / Efficiency |

| Shaded Pole | Low starting torque | Low efficiency (~30%), suitable for low-demand loads |

| Split Phase | Low starting torque, high starting current | Moderate efficiency, suitable for low torque needs |

| Capacitor Start | High starting torque (up to 4x normal) | Relatively low operating efficiency, higher energy use at startup |

| Permanent Split Capacitor (PSC) | Low starting torque | Better efficiency than shaded pole, low starting current |

Shaded-pole motors: These asynchronous motors provide low starting torque and low efficiency. They suit small fans and appliances with minimal load.

Split-phase motors: These asynchronous motors deliver moderate efficiency and low starting torque. They work well in low-torque applications such as washing machines.

Capacitor-start motors: These asynchronous motors generate high starting torque, making them ideal for compressors and pumps. They consume more energy during startup.

Permanent split capacitor (PSC) motors: These asynchronous motors balance efficiency and low starting current. They serve in HVAC blowers and fans.

Note: Brushless electric motor technology, often called BLDC, falls under ac motors. BLDC motors use electronic controllers for precise speed and torque control. They offer high efficiency, low noise, and long lifespan. However, they require complex control systems and have higher initial costs compared to traditional ac motors.

Ac motors, including synchronous motors, induction motors, and their subtypes, provide solutions for a wide range of electric motor applications. Synchronous ac motors deliver precision and efficiency, while asynchronous motor designs offer durability and simplicity. The choice of motor subtype depends on the required starting torque, efficiency, and application environment.

Types of DC Motors

DC motors play a vital role in modern industry and consumer products. Engineers select from several types of dc motors based on performance requirements, control needs, and application environments. Each type offers distinctive characteristics that influence speed regulation, torque output, and suitability for specific electric motor applications.

Series DC Motors

Series DC motors feature a field winding connected in series with the armature. This design causes the field current to equal the armature current, resulting in very high starting torque. The torque output increases rapidly as the armature current rises, making these motors ideal for heavy-duty tasks. However, speed varies widely with load. At no load, the speed can increase dangerously, so operators must always connect a load to prevent overspeed.

| Parameter | Series DC Motor |

| Field Winding Connection | Series with armature |

| Starting Torque | Very high |

| Speed Regulation | Poor; speed varies widely with load |

| Typical Applications | Cranes, hoists, locomotives, electric bikes and cars |

Series dc motors excel in applications requiring high starting torque, such as cranes and elevators. Their dynamic response suits tasks with frequent starts and stops. However, they do not perform well in constant speed operations or variable speed drives.

⚡ Tip: Always ensure a load is connected to a series DC motor to avoid overspeed and potential damage.

Shunt DC Motors

Shunt DC motors use a field winding connected in parallel (shunt) with the armature. The field current remains independent from the armature current, which allows for better speed regulation. These motors maintain nearly constant speed under varying loads, although speed decreases slightly as load increases. Shunt dc motors require careful starting under heavy loads due to the need for large starting current.

| Parameter | Shunt DC Motor |

| Field Winding Connection | Parallel (shunt) with armature |

| Starting Torque | Low and constant |

| Speed Regulation | Good; speed remains nearly constant |

| Typical Applications | Fans, blowers, elevators, centrifugal pumps, lathes |

Shunt dc motors suit applications where constant speed is essential, such as fans and pumps. Their simplified reversing control and ability to support regenerative drives make them popular in industrial settings.

Note: Shunt dc motors provide reliable performance in electric motor applications that demand steady speed and moderate torque.

Compound DC Motors

Compound DC motors combine the features of series and shunt dc motors by incorporating both series and shunt field windings. This design delivers high starting torque from the series field and good speed regulation from the shunt field. Compound dc motors balance these traits, offering versatile performance for varying load conditions.

| Parameter | Compound DC Motor |

| Field Winding Connection | Combination of series and shunt |

| Starting Torque | High (not as high as pure series) |

| Speed Regulation | Moderate to good |

| Typical Applications | Heavy-duty gear, automotive starters, variable load |

Compound dc motors adapt well to industrial gear systems and automotive starters. Their robust torque characteristics and adaptability make them suitable for electric motor applications with fluctuating loads. Operators can adjust winding configurations to optimize performance, although these motors may require increased maintenance.

⚙️ Compound dc motors offer a practical solution when both high starting torque and effective speed regulation are needed.

Permanent Magnet DC Motors

Permanent magnet DC motors use permanent magnets to supply field flux, eliminating the need for field windings. This design reduces size and cost, especially for small ratings. Permanent magnet dc motors deliver excellent starting torque and good speed regulation. However, torque remains limited to prevent demagnetization of the magnets.

| Feature/Aspect | Permanent Magnet DC Motor |

| Field Flux | Provided by permanent magnets |

| Starting Torque | High |

| Speed Regulation | Good; speed controlled by armature voltage |

| Efficiency | High; no field copper losses |

| Size and Weight | Compact, lightweight |

| Typical Applications | Electric toothbrushes, vacuum cleaners, toys, automotive components |

Permanent magnet dc motors excel in small, low-power electric motor applications. Their compact and lightweight design suits portable tools and household devices. Engineers use rare-earth magnets to enhance performance in size-sensitive and high-performance products. These motors operate efficiently, quietly, and require minimal maintenance.

Permanent magnet dc motors provide a consistent magnetic field without energy input.

They offer improved performance and operate over wide temperature ranges.

Common uses include computer drives, automotive components, and smart appliances.

Permanent magnet dc motors power electric vehicles, praised for their efficiency and cost optimization.

DC Motor Comparison Table

| Motor Type | Construction/Field Connection | Speed Regulation | Torque Output Characteristics | Typical Applications |

| Series DC Motor | Field winding in series with armature | Poor; speed varies widely with load | Very high starting torque; speed varies with load | Cranes, hoists, locomotives, electric bikes and cars |

| Shunt DC Motor | Field winding in parallel (shunt) | Good; nearly constant speed | Low and constant starting torque; torque increases with speed | Fans, blowers, elevators, centrifugal pumps, lathes |

| Compound DC Motor | Combination of series and shunt fields | Moderate to good | High starting torque; balanced speed regulation | Heavy-duty gear, automotive starters, variable load |

| Permanent Magnet DC | Uses permanent magnets for field flux | Good; speed controlled by armature voltage | High starting torque; limited load capacity | Electric toothbrushes, vacuum cleaners, toys, automotive components |

DC motors offer engineers a range of options for electric motor applications. Series dc motors deliver powerful starts for heavy loads. Shunt dc motors maintain steady speed for fans and pumps. Compound dc motors balance torque and speed regulation for versatile tasks. Permanent magnet dc motors provide efficient, compact solutions for small devices and automotive components.

Different Types of Special Purpose Motors

Special motors serve electric motor applications that demand precision, unique control, or adaptability. These motors often operate under demanding duty cycles, which involve repeated phases of starting, running, and braking. Proper thermal management becomes essential, as frequent cycling can raise temperatures and affect longevity. Selecting the right special motors ensures reliable performance and extends service life.

Stepper Motors

Stepper motors move in precise, discrete steps, making them ideal for applications that require accurate positioning. Each step represents a fixed angle, such as 1.8°, allowing for high-resolution control. Stepper motors use different rotor types: permanent magnet, variable reluctance, and hybrid. Permanent magnet rotors offer good holding torque, while variable reluctance rotors provide higher speed and resolution. Hybrid rotors combine both features for superior performance. Stepper motors operate in open-loop systems, so they do not need feedback devices. However, they can lose position if overloaded or run at high speeds. These special motors excel in 3D printers, CNC machines, and camera platforms.

Stepper motors deliver reliable, cost-effective motion control but may stall or lose accuracy under heavy loads.

Servo Motors

Servo motors provide precise control of position, speed, and torque through closed-loop feedback systems. They use encoders or resolvers to monitor movement and adjust in real time. This feedback enables servo motors to maintain accuracy even when loads change. Their construction includes rare earth magnets and high torque density, supporting dynamic and high-speed operations. Servo motors suit robotics, automation, and conveyor systems where repeatability and adaptability are critical. Although more complex and costly than stepper motors, servo motors offer superior performance for demanding tasks.

| Characteristic | Stepper Motor (Open-Loop) | Servo Motor (Closed-Loop) |

| Feedback | None | Continuous (encoder/resolver) |

| Position Accuracy | Assumed by step count | Measured and corrected in real time |

| Load Adaptability | Limited | High |

| System Complexity | Low | High |

| Cost | Lower | Higher |

Universal Motors

Universal motors operate on both AC and DC power supplies. Their series-wound design delivers high starting torque and speeds above 3500 rpm. These special motors perform well in portable tools, household appliances, and devices that require compact size and variable speed. Universal motors can run at high speeds on AC and maintain similar performance on DC at equivalent voltages. Their versatility makes them a popular choice for blenders, drills, and vacuum cleaners.

Universal motors combine flexibility with powerful performance, making them suitable for many consumer products.

Synchronous Reluctance Motors

Synchronous reluctance motors feature a cage-type rotor and auxiliary windings, similar to induction motors. These special motors synchronize with the supply frequency, providing stable speed and efficient operation. Synchronous reluctance motors find use in lifts, wind turbines, and traction systems for railways and industrial vehicles. Their robust design supports gearless drives and renewable energy projects. Engineers value these motors for their reliability and ability to handle demanding duty cycles.

Synchronous reluctance motors support applications that require synchronization and efficient energy use.

They play a key role in modern transportation and renewable energy sectors.

Selecting the right electric motor depends on understanding the distinctive characteristics of each type. AC motors offer durability and low maintenance, making them ideal for continuous industrial use. DC motors provide precise speed and torque control, which suits applications needing rapid response. Special motors deliver advanced control for tasks like robotics. The table below highlights key selection factors:

| Factor | DC Motor Characteristics | AC Motor Characteristics |

| Power Source | Uses direct current (battery or rectified supply) | Uses alternating current (grid supply) |

| Speed Control | Excellent, via voltage/current adjustments | Requires variable frequency drive (VFD) or inverter |

| Maintenance | Higher due to brushes and commutators | Lower, brushless and simpler design |

For electric motor applications, matching motor type to load, speed, and environment ensures reliable performance and cost efficiency.

FAQ

What are the main electric motors types used in industry?

Industry often uses ac motors, dc motors, and special motors. Each type offers distinctive characteristics. Ac induction motors provide durability. Dc motors deliver high torque. Special motors support precision tasks. Selection depends on electric motor applications and performance needs.

How do synchronous motors differ from induction motors?

Synchronous motors operate at a constant speed matching the supply frequency. Induction motors, also called asynchronous motor types, run slightly slower due to slip. Synchronous ac motors suit precise speed control. Ac induction motors work well in general-purpose electric motor applications.

Where are brushless electric motor designs most effective?

Brushless electric motor designs excel in applications needing high efficiency and low maintenance. These motors appear in robotics, electric vehicles, and HVAC systems. Their advanced controllers provide precise speed and torque, making them ideal for modern electric motor applications.

What are the distinctive characteristics of special motors?

Special motors offer unique features such as stepwise movement, feedback control, or compatibility with both AC and DC power. These distinctive characteristics make them essential for robotics, automation, and other electric motor applications requiring accuracy and adaptability.

Why choose different types of electric motors for specific tasks?

Engineers select different types of electric motors based on load, speed, and control requirements. Ac motors handle continuous operation. Dc motors provide rapid response. Special motors deliver advanced control. Matching motor type to application ensures optimal performance and reliability.