What is the process of laminating the stator and rotor cores?

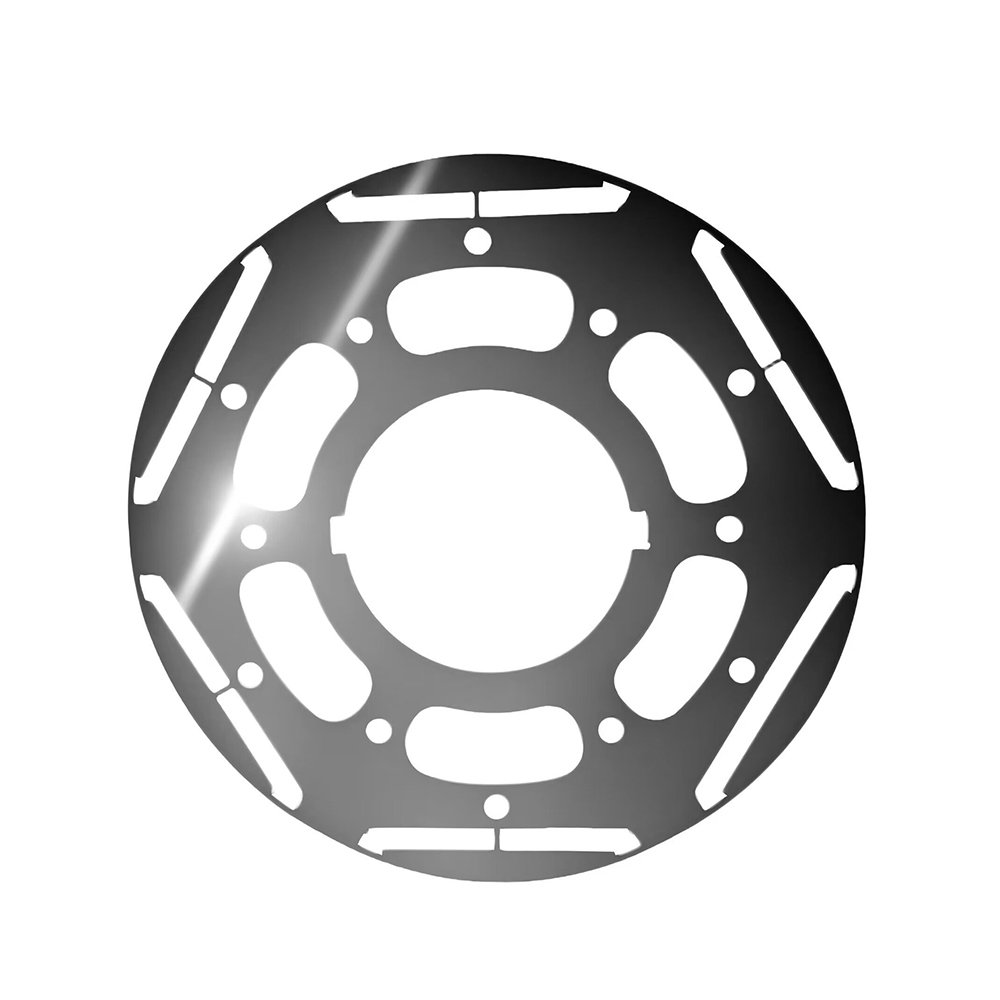

The motor stator and rotor core parts adopt high-precision, high-efficiency and long-life multi-station progressive dies, and are automatically punched on high-speed punch presses. It is a concrete application of modern stamping technology. The punching process is that after the strip material comes out of the coil, it is first leveled by a leveling machine, and then fed by an automatic feeding device. After the strip material enters the die, it can be completed in succession. Punching, forming, finishing, trimming, automatic lamination of the core, blanking of laminations with twisting, blanking of laminations with reverse laminations and other processes, the entire punching process is automatically completed by the high-speed punch press.

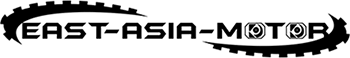

The rotor sheet is a commonly used anti-interference component in electronic circuits, which has an excellent inhibitory effect on high-frequency noise and is generally made of ferrite materials. The rotor core punch is not a professional term in the electrical industry. The rotor core punch is also a type of rotor core. The rotor core punch (magnetic core) is the cornerstone of the entire motor, which is used to increase the magnetic flux of the inductor coil and achieve the maximum conversion of electromagnetic force. The motor core is usually a combination of a stator and a rotor. The stator is usually a non-rotating part, and the rotor is usually embedded inside the stator.

In the motor industry, the stator and rotor core is one of the important parts of the motor, and the lamination of the stator and rotor core is an important step in the use process. The following is the process preparation for lamination:

1. Check the spot welding quality of the pressing tooth plate, stator ventilation slot plate, and punching plate. If there is desoldering, it should be returned.

2. Check that the relevant equipment and tooling are in good condition.

3. During lamination, the punching burr direction is consistent.

4. If there are broken pieces, broken teeth or cracks on the punching plate, they must be removed. If the paint film is damaged or the paint film thickness is seriously uneven, it must be removed. If there is oil on the surface, wipe it off before use.

5. After lamination, use a forming rod to clean the groove shape. Use a groove rod to check that each groove shape must pass, and individual files that cannot pass can be partially repaired.