Overcoming Casting Challenges: Ensuring Rotor Quality at East-Asia Motor Manufacturing

This article details East-Asia Motor Manufacturing's successful resolution of quality issues in cast aluminum rotors for a key client. By implementing advanced process monitoring, optimizing pouring parameters, and enhancing mold design, the team effectively eliminated cavities, bubbles, and weight deviations. Continuous data analysis and teamwork played vital roles in improving product reliability and consistency. The initiative not only bolstered client trust but also reinforced the company's commitment to excellence in motor component production. The experience underscores the importance of meticulous process control and collaborative effort in addressing manufacturing challenges within a competitive industry landscape.

At East-Asia Motor Manufacturing, our unwavering pursuit of excellence drives us to enhance the performance and quality of every product we produce. As a frontline technician, I understand well that each parameter is crucially linked to the final product's reliability and customer satisfaction. Recently, during our collaboration with a prominent client, we encountered significant challenges related to the stability of the quality of cast aluminum rotors. Through team collaboration and continuous process optimization, we ultimately resolved these issues, ensuring that every rotor meets the required standards.

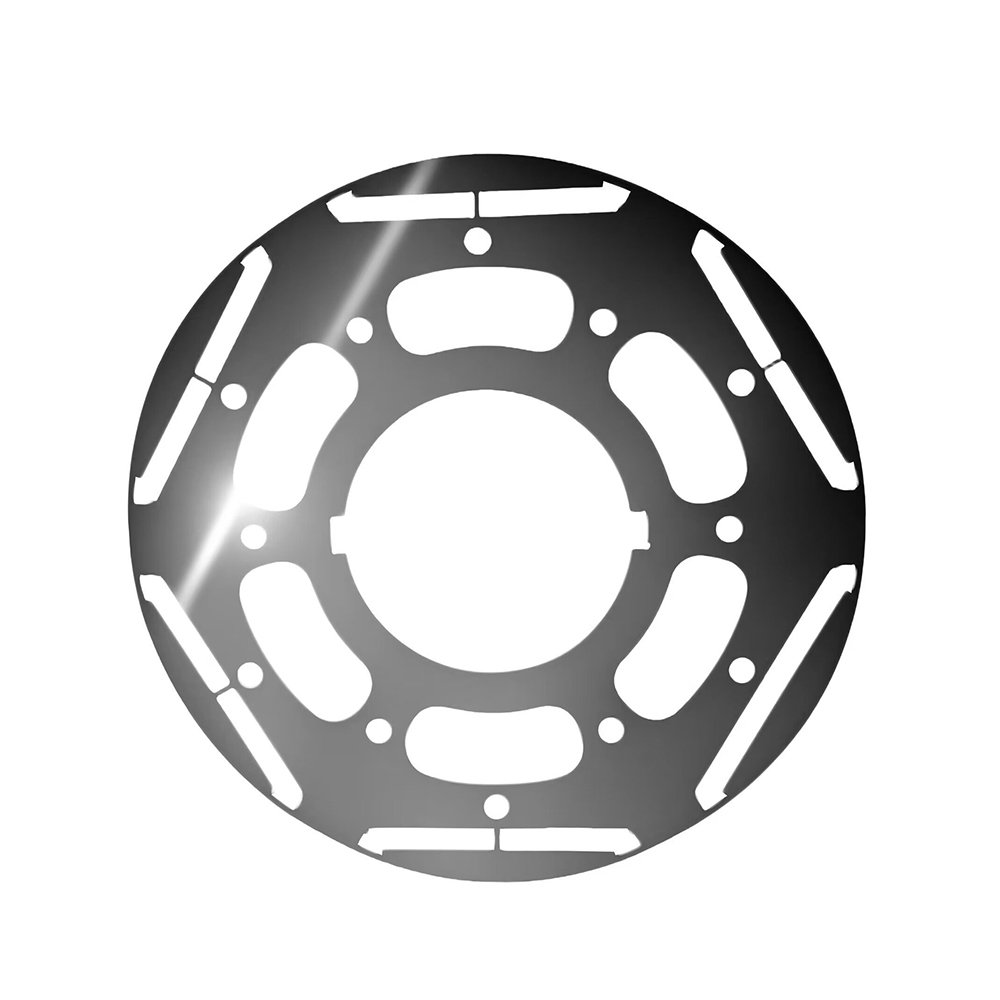

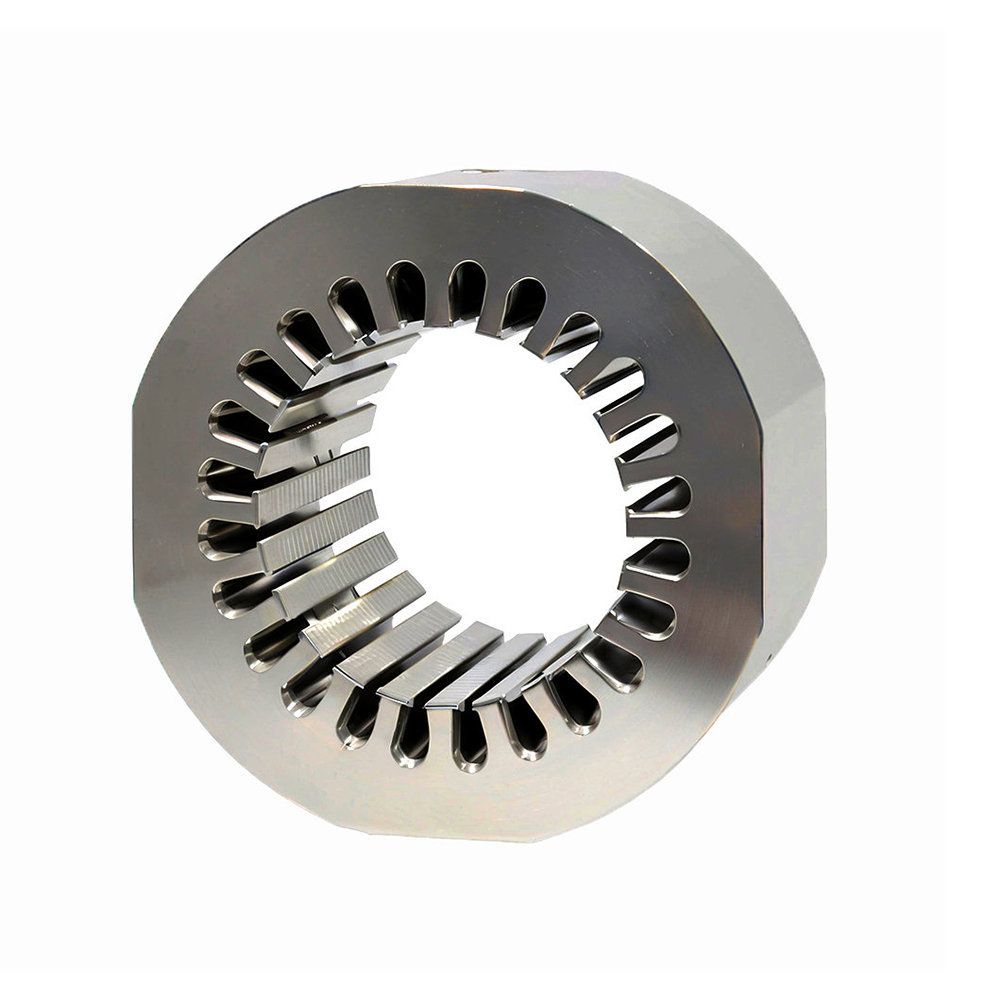

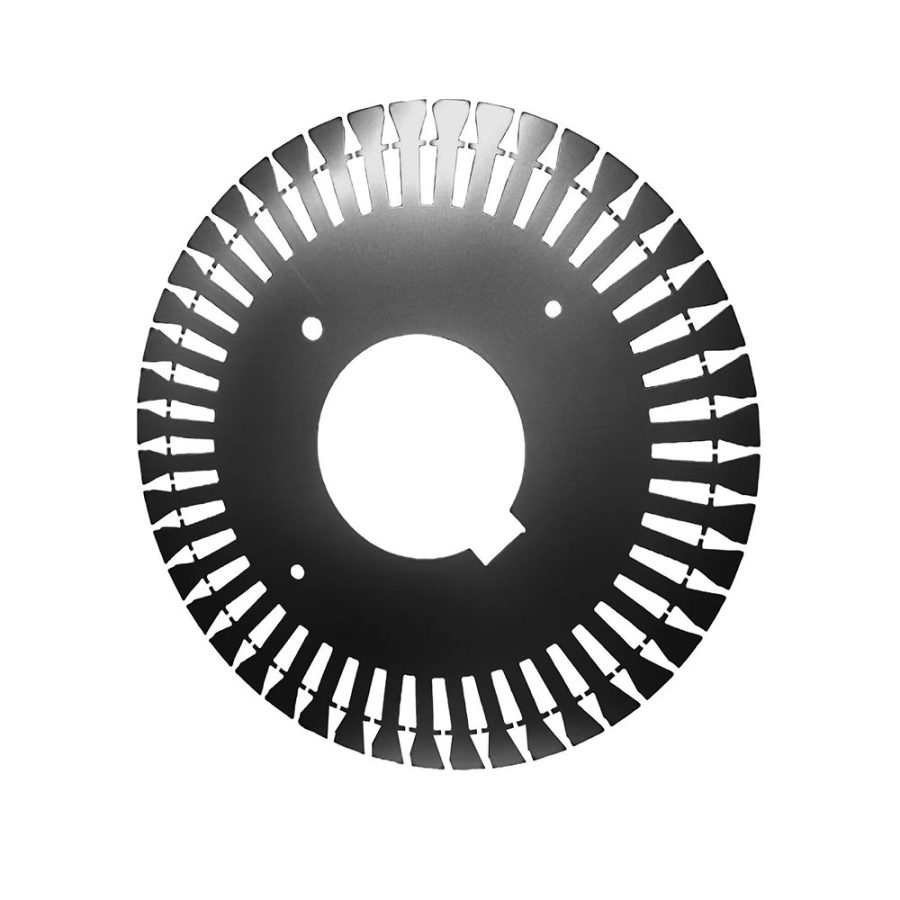

The origin of the problem traces back to the casting of rotors for a renowned customer. This client set out two key requirements: first, the cast aluminum rotors must be free of cavities and bubbles to guarantee mechanical strength and thermal conductivity; second, the weight deviation should be minimized as much as possible to maintain consistency and reliability during installation and operation. We clearly understood that meeting these specifications in actual production posed considerable difficulties.

The core issue lay in the fluctuations in rotor weight caused by variations in the number of slices and differences in pouring pressure during casting. Each inspection revealed that some rotors were either underweight or overweight, with defects such as cavities and bubbles appearing intermittently. These issues not only compromised product performance but also heightened the risks of rework and scrap.

To address the challenge, we swiftly organized a technical investigation team. Our analysis led us to the conclusion that inconsistencies could arise from multiple factors, including pouring pressure, temperature, and mold cooldown speed across different batches. Particularly, the weight of each rotor segment is influenced by numerous variables, making it difficult to ensure uniformity solely based on experience.

In response, we devised a comprehensive monitoring system. We established a baseline control mechanism based on the formula: “Single segment weight × Theoretical segment count = Total component weight.” This approach set the theoretical weight of each batch of cast rotors as the target. Prior to casting, we measured the estimated weight of each mold and formulated detailed process parameters.

During production, we integrated real-time monitoring equipment such as pressure sensors and temperature sensors to track the fluctuations in pouring pressure and mold temperature. Data collection allowed us to identify anomalies promptly—be it pressure surges or temperature deviations—enabling immediate adjustments to optimize the process.

Furthermore, we paid extra attention to the purity and flowability of the molten aluminum. We implemented venting holes and improved the design of the pouring spout to facilitate the swift expulsion of trapped air, which significantly reduced the formation of cavities and bubbles. During process adjustments, multiple trials were conducted to find the optimal combination of pouring pressure and cooling rate.

Through relentless efforts, the stability of the production line markedly improved. Adjusting the pouring pressure within an appropriate range yielded a notable reduction in weight fluctuations among different batches. After each production cycle, we meticulously inspected the cast aluminum layers for integrity and smoothness, analyzing data rigorously to enhance our process continually.

The culmination of these efforts produced satisfying results: the finished rotor castings no longer exhibited issues like bubbles or cavities, and overall quality was significantly elevated. The weight deviations were maintained within the acceptable range set by the customer, greatly strengthening their trust in our products. This series of improvements not only boosted technical performance but also reinforced our commitment to delivering consistent quality to our clients.

Throughout this process, I came to appreciate the vital role of teamwork. Every process engineer, quality inspector, and maintenance staff member actively contributed—focusing on details and data analysis to drive resolution. It reaffirmed my belief that continuous learning and persistent optimization are essential to remaining competitive in a fierce market.

Every challenge presents an opportunity for growth. Witnessing the smiling satisfaction of our clients and hearing their praise for our product quality fills me with a deep sense of accomplishment. Moving forward, we will continue refining our cast aluminum procedures to supply even better products, constantly striving for excellence. East-Asia Motor Manufacturing, with its professional expertise and steadfast conviction, is poised to explore broader horizons in the field of motor manufacturing.