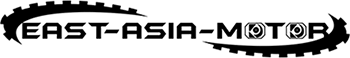

What Are the Main Types of Stator Winding Processes and Their Features

Stator winding processes are vital for optimizing electric motor performance, balancing efficiency, cost, and complexity. Single-layer windings offer simplicity, ideal for low-power applications, while double-layer windings enhance magnetic robustness for high-performance needs. Distributed windings produce smoother operation and reduce noise, suitable for precision motors like electric vehicles, whereas concentrated windings excel in compact, cost-sensitive designs. Advanced methods such as flat-wire windings push efficiency boundaries with higher slot fill factors and better thermal management. Technologies like needle winding automate precision, increasing production speed and consistency. Selecting the appropriate winding type depends on specific application demands, with each method offering unique advantages to meet modern motor performance standards.

Engineers and manufacturers select from several main types of stator winding process, each offering unique features for electric motor performance. The most common options include single-layer and double-layer windings, salient-pole and non-salient-pole designs, as well as advanced flat-wire winding technologies.

| Winding Type | Highlights |

| Single-Layer Winding | Simplifies manufacturing |

| Double-Layer Winding | Enhances magnetic field |

| Salient-Pole Winding | Enables precise magnetic control |

| Non-Salient-Pole Winding | Provides structural simplicity |

| Flat-Wire Winding | Boosts efficiency with innovation |

Single-phase stators often serve small generators and light commercial equipment, while three-phase stators dominate industrial and large-scale applications due to superior efficiency and power output.

Key Takeaways

Understand the differences between winding types. Single-layer windings are simple and cost-effective, while double-layer windings enhance efficiency and magnetic balance.

Choose the right winding for your application. Concentrated windings suit compact motors, while distributed windings excel in high-performance scenarios like electric vehicles.

Consider advanced methods like flat-wire winding. This modern approach improves heat dissipation and power density, making it ideal for compact and efficient motor designs.

Utilize needle winding technology for precision. Automated needle winding increases production speed and consistency, reducing manual labor in motor assembly.

Types of Stator Winding Process

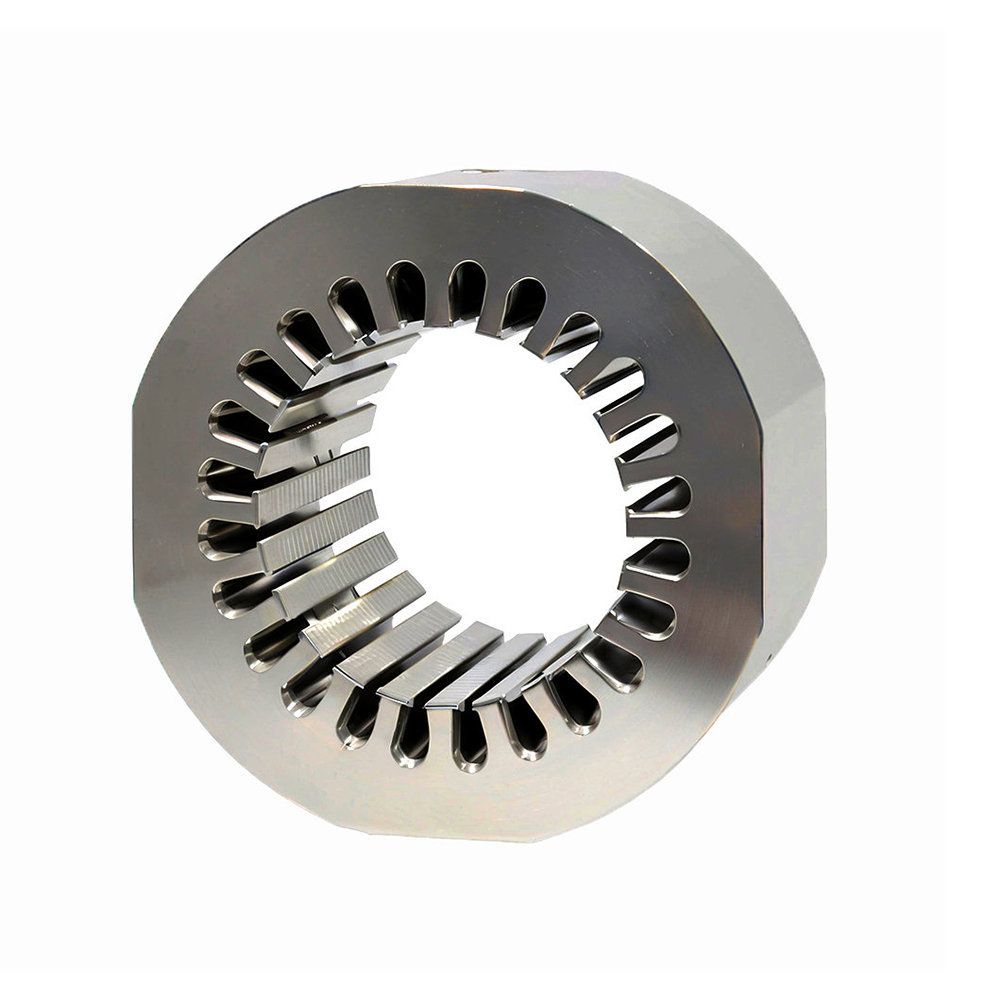

Electric motor performance depends heavily on the types of stator winding process used during manufacturing. Each process offers unique structural and operational characteristics. Understanding these differences helps engineers select the most suitable winding method for specific applications. The main categories include concentrated winding, distributed winding, single-layer winding, and double-layer winding. The following sections provide a detailed look at each type.

Concentrated Winding

Concentrated winding stands out for its specific arrangement and suitability for certain slot and pole combinations. Manufacturers often choose this type of stator winding process for its simplicity and cost-effectiveness.

Concentrated windings feature coils wound around individual teeth.

The feasibility of this process depends on the relationship between the number of slots and poles.

This method can reduce losses and optimize performance, but it works best with conventional slot-pole combinations.

| Feature | Concentrated Winding | Distributed Winding |

| Structure | Each coil wound around a single tooth | Coils spread over multiple slots or teeth |

| Back-EMF Shape | Trapezoidal | Sinusoidal |

| Harmonics | Higher harmonic content | Lower harmonic distortion |

| Torque Ripple | More torque ripple | Smoother torque output |

| Copper Usage | Lower—shorter coil length | Higher—longer distributed windings |

| Thermal Management | Localized heating | Better thermal distribution |

| Manufacturing Cost | Lower, simpler to automate | Higher, more complex layout |

| Ideal Applications | Compact, low-cost motors (e.g., appliances) | High-performance motors (e.g., EVs, robotics) |

Concentrated winding offers a practical solution for compact, low-cost motors but introduces higher harmonic content and torque ripple compared to other types of stator winding process.

Distributed Winding

Distributed winding spreads the coils across multiple slots, creating a more uniform magnetic field. This approach improves several key performance metrics and is common in high-performance electric motors.

| Comparison Item | Concentrated Winding | Distributed Winding |

| Structure | Windings placed in specific slots | Windings spread across multiple slots |

| Winding Process | Simple process, suited for automation | Complex, harder to insert |

| Magnetic Field | More concentrated, higher fluctuation | More uniform, smoother operation |

| Torque Ripple | Higher ripple (obvious cogging torque) | Stable torque, ideal for precision |

| Electromagnetic Noise | Higher noise, needs extra damping | Quieter operation |

| Performance Metric | Improvement Description |

| Efficiency | Increased overall efficiency and reduced harmonic distortion due to uniform magnetic field distribution. |

| Torque Ripple | Smoother torque production with minimized fluctuations, leading to quieter operation. |

| Cooling Performance | Enhanced cooling efficiency through better airflow and even heat dissipation across the motor. |

Distributed winding excels in applications where smooth operation, efficiency, and noise reduction are critical. This type of stator winding process is often found in electric vehicles and robotics.

Single-Layer Winding

Single-layer winding uses one coil per slot, resulting in a straightforward and compact design. This method is especially popular in low-power and low-voltage motors.

| Feature | Description |

| Coil per Slot | One coil per slot, simple design |

| Turns | Fewer turns, compact and efficient |

| Application | Used in low-power, low-voltage motors |

| Manufacturing Cost | Easier and cost-effective to manufacture |

Single-layer windings are ideal for small AC motors, low-voltage devices, and projects focused on cost efficiency.

They provide a practical and economical solution for electric motor designs where simplicity, cost, and size are prioritized.

This type of stator winding process remains a top choice for manufacturers seeking to minimize production costs without sacrificing basic functionality.

Double-Layer Winding

Double-layer winding places two coil sides in each slot, improving magnetic balance and efficiency. This structure is better suited for three-phase systems and high-performance applications.

| Feature | Single Layer Winding | Double Layer Winding |

| Structure | One conductor wraps continuously per layer | Two coil sides share the same slot |

| Efficiency | Suitable for simple coils, lower slot fill | Improves magnetic balance, better suited for three-phase systems |

| Cost | Generally lower due to simpler design | Higher due to increased complexity and materials used |

| Challenge | Explanation |

| Additional insulation | Requires a separator between coil sides, taking up space that could be used for copper. |

| Coil spacing | End-turns on double layer windings are closer together, necessitating better insulation. |

| Increased coil count | Double layer winding results in twice as many coils to tape, complicating the manufacturing process. |

The copper saved from smaller inner coils is offset by the additional copper needed for the outer coils.

Concentric windings are generally easier to manufacture for small diameter stators due to reduced complexity in laying coils.

The setup for winding coils with different spans and turns adds to the complexity.

Double-layer winding increases the complexity and cost of the stator, but it delivers improved efficiency and magnetic performance. This type of stator winding process is essential for demanding industrial and commercial applications.

Advanced Winding Methods

Lap Winding

Lap winding connects conductors so that the number of parallel paths equals the number of poles. This method appears most often in low voltage, high current machines. Engineers select from simplex, duplex, or triplex lap winding, depending on the application’s current requirements.

| Aspect | Description |

| Definition | Connects conductors so parallel paths and poles are equal in number |

| Applications | Used in low voltage, high current machines |

| Types | Simplex, Duplex, Triplex |

Lap winding offers robust performance for industrial motors that demand high current. The arrangement allows for easy repair and maintenance, making it a reliable choice for heavy-duty equipment.

Wave Winding

Wave winding differs from lap winding in both coil arrangement and current flow. In wave winding, each coil connects to non-adjacent segments, creating only two parallel paths regardless of the number of poles. This design suits high voltage, low current applications.

| Feature | Lap Winding | Wave Winding |

| Coil Arrangement | Adjacent segments | Non-adjacent segments |

| Current Flow | Multiple parallel paths | Two parallel paths |

| Application Suitability | Low voltage, high current | High voltage, low current |

Wave winding finds use in automotive alternators, starter generators, and modern electric vehicle motors. The method supports both distributed and non-distributed windings, offering flexibility in design. Flat wire wave winding increases fill factor and efficiency, which improves thermal management and reduces copper losses. Manufacturers favor this method for its ability to enhance automation and consistency in stator assembly.

Needle Winding

Needle winding technology brings precision and flexibility to stator production. The process uses automated needle insertion to route wires with high accuracy, addressing challenges like low efficiency and poor accuracy found in traditional methods.

High-precision control and efficient automation

Dynamic trajectory planning for improved winding quality

Machine learning integration for process optimization

Needle winding enables electromagnetically optimized windings and supports advanced wire stratification. However, the process can face challenges such as high reliance on skilled labor, inconsistent precision, and slow changeovers. Maintenance issues may also cause production delays, especially in high-volume manufacturing.

Formed Coil Winding

Formed coil winding involves shaping coils precisely before inserting them into stator slots. This approach allows for better control of wire placement and improved thermal characteristics. Manufacturers benefit from faster setup times, consistent production rates, and reduced operator fatigue.

Enhanced electrical performance due to controlled dimensions

Lower scrap rates through precise coil shaping

Sustainable production levels for large-scale operations

Formed coil winding supports the latest advancements in the types of stator winding process, including optimal slot filling and improved heat dissipation. These features contribute to higher efficiency and longer motor lifespan.

Stator Winding Features

Salient-Pole

Salient-pole windings feature poles that project outward from the stator core. This design appears frequently in synchronous machines, especially those operating at low and medium speeds. Engineers value salient-pole windings for their ability to deliver precise magnetic control and flexible performance. The unique geometry influences both power output and reactive power characteristics.

Salient-pole windings allow for advanced control of machine dynamics. Operators can adjust excitation and load angle to optimize performance for specific applications.

Non-Salient-Pole

Non-salient-pole windings, also known as cylindrical rotor windings, present a smooth rotor surface. This configuration supports high-speed operation and robust mechanical integrity. Manufacturers often select non-salient-pole windings for demanding environments where reliability and efficiency are critical.

| Application Type | Reason for Preference |

| High-speed applications | Robust structure and higher mechanical integrity |

| Thermal power plants | Suitable for high-speed mechanical applications |

| Gas turbine generators | Higher mechanical strength and improved cooling |

| Turbo generators | Simplicity of design and robustness |

| Large industrial motors | Enhanced performance in high-speed scenarios |

| Aerospace applications | Required for high-speed operations |

| High-speed trains | Necessary for efficient operation at high speeds |

| Electric power grids | Essential for stability and performance in high-speed |

Non-salient-pole windings excel in scenarios where speed and durability matter most. Their design minimizes vibration and supports efficient cooling, making them ideal for large-scale industrial and transportation systems.

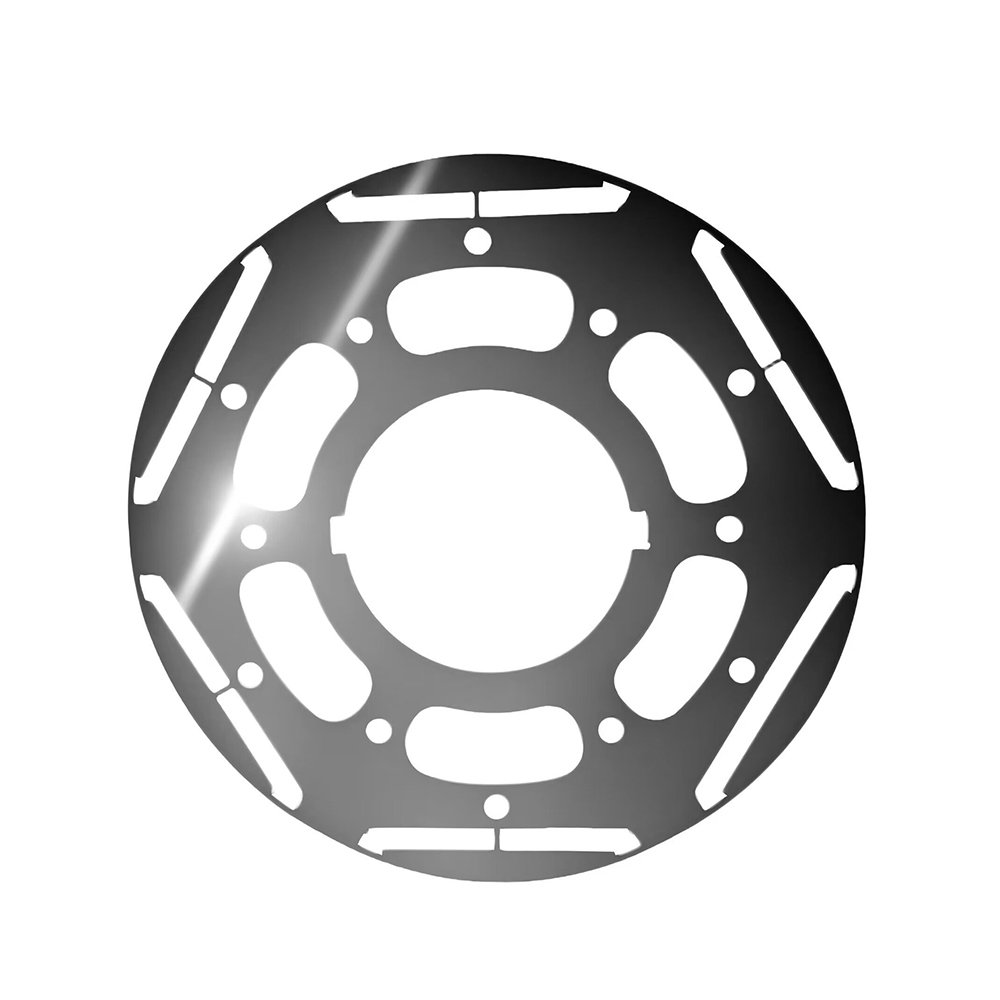

Flat-Wire

Flat-wire windings represent a modern advancement in the types of stator winding process. This approach uses ribbon-like wires instead of traditional round conductors, resulting in several performance benefits. The increased surface area improves heat dissipation and enables a more compact motor design. Engineers achieve higher slot fill rates, which boosts power density and efficiency.

Flat-wire windings reduce electrical resistance and enhance overall motor efficiency. The compact structure supports better thermal management, but higher power density demands effective cooling strategies.

High slot fill rate, often exceeding 70%, increases power density and improves heat dissipation.

Stronger heat dissipation capacity results from reduced thermal resistance compared to round wire stators.

Enhanced power torque capability allows for increased rotor space and improved peak output.

| Aspect | Description |

| Slot Fill Factor | Flat wire windings provide a high slot fill factor, enhancing power density and efficiency. |

| AC Loss Complexity | AC loss calculations are more complex for flat wire, especially at high frequencies due to eddy currents. |

| Heat Dissipation | The compact structure of flat wire improves heat dissipation, but higher power density increases thermal loads. |

| Thermal Management Needs | Effective thermal management strategies are necessary to prevent overheating and maintain performance. |

Flat-wire windings continue to shape the future of electric motor design, offering solutions for applications that demand high efficiency and advanced thermal management.

Selecting the right stator winding process shapes motor efficiency, torque, and reliability. Each method offers unique advantages and trade-offs:

| Winding Type | Advantages | Disadvantages |

| Focused Winding | Easier to produce, less copper usage, high torque density | More torque ripple |

| Dispersed Winding | Smoother electromagnetic field, reduced noise | More complex manufacturing, longer winding overhangs |

Engineers must weigh factors such as production requirements, equipment needs, and application demands. For example, high slot fill increases torque density but complicates manufacturing. The right choice ensures optimal performance for applications ranging from household appliances to industrial compressors.

FAQ

What is the main difference between concentrated and distributed winding?

Distributed winding spreads coils across multiple slots, creating a smoother magnetic field. Concentrated winding places coils on individual teeth, which increases torque ripple. Engineers select distributed winding for high-performance motors and concentrated winding for compact, cost-effective designs.

Tip: Distributed winding reduces electromagnetic noise in electric vehicles.

Why do manufacturers prefer flat-wire windings in modern motors?

Flat-wire windings offer higher slot fill rates and better heat dissipation. This design increases power density and efficiency. Manufacturers use flat-wire windings in applications that demand compact size and advanced thermal management, such as electric vehicles and robotics.

| Feature | Flat-Wire Winding |

| Slot Fill Rate | High |

| Heat Dissipation | Excellent |

| Efficiency | Improved |

How does double-layer winding improve motor performance?

Double-layer winding places two coil sides in each slot. This arrangement enhances magnetic balance and efficiency. Engineers use double-layer winding in three-phase systems to achieve better torque output and smoother operation.

Can needle winding technology increase production speed?

Needle winding technology automates wire placement with high precision. This process reduces manual labor and increases consistency. Manufacturers achieve faster production rates and improved winding quality, especially in large-scale motor assembly.

Note: Automated needle winding minimizes human error and supports advanced motor designs.