The outer diameter of the core and stator of the new energy vehicle drive is Φ130~Φ500, and most of them are permanent magnet motor structures, and there are also asynchronous induction structures. The thickness of the silicon steel sheets used is 0.5mm, 0.35mm, 0.30mm, 0.27mm, etc. The progressive punching and self-riveting process can realize the segmented rotary stack riveting in the mold.

Processing capabilities

Segmented rotary stack riveting technology in the core progressive punching die

Top cylinder system for the core progressive die

Online pressurization, stack height detection, automatic laser coding

Multi-station automatic TG argon arc welding technology

Core press-fit automatic laser welding production line technology

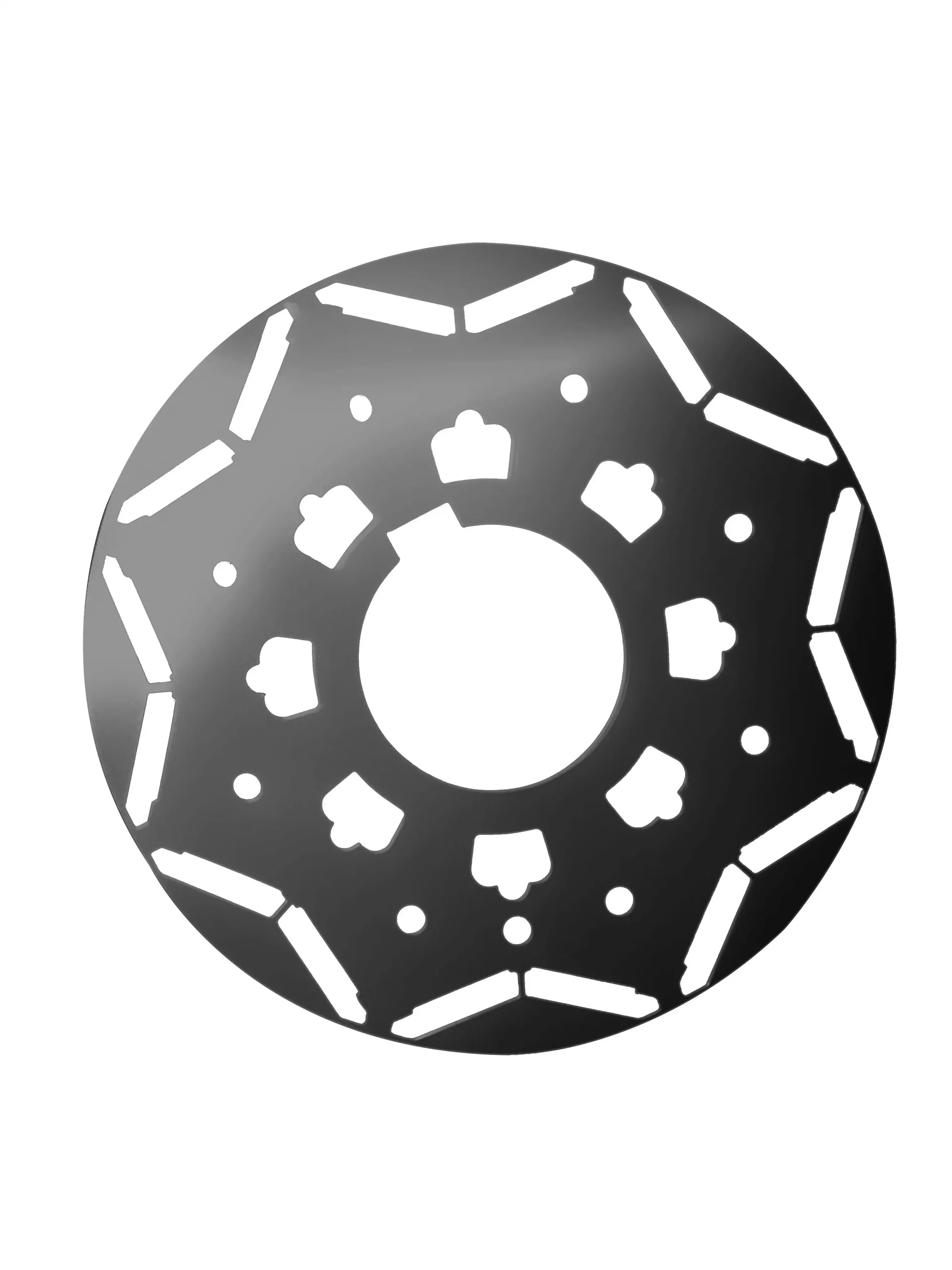

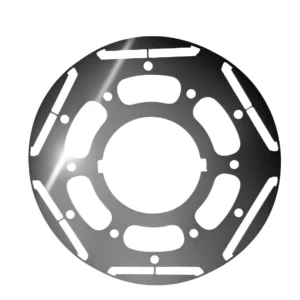

Rotor Stamping sheet

Application Scope

New energy passenger cars and commercial vehicles