JM36 Series Double-Point High-Performance Gantry Press

1. The motor core manufactured by the JM36 series gantry double-point press provides you with the following core value with the core technology of the equipment:

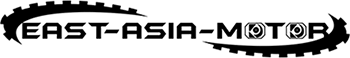

Ultra-high precision core: ±0.01mm repeat positioning accuracy + dynamic parallelism compensation, axial runout of the core after lamination ≤0.03mm, air gap uniformity increased by 30%, motor efficiency increased by 0.5%-1.2% (IE5/IE6 energy efficiency compliance rate 100%).

Zero defect burr control: punching burr ≤0.015mm (0.35mm silicon steel sheet), direct lamination without secondary processing, lamination coefficient ≥98.5%, iron loss reduced by 10%-15%.

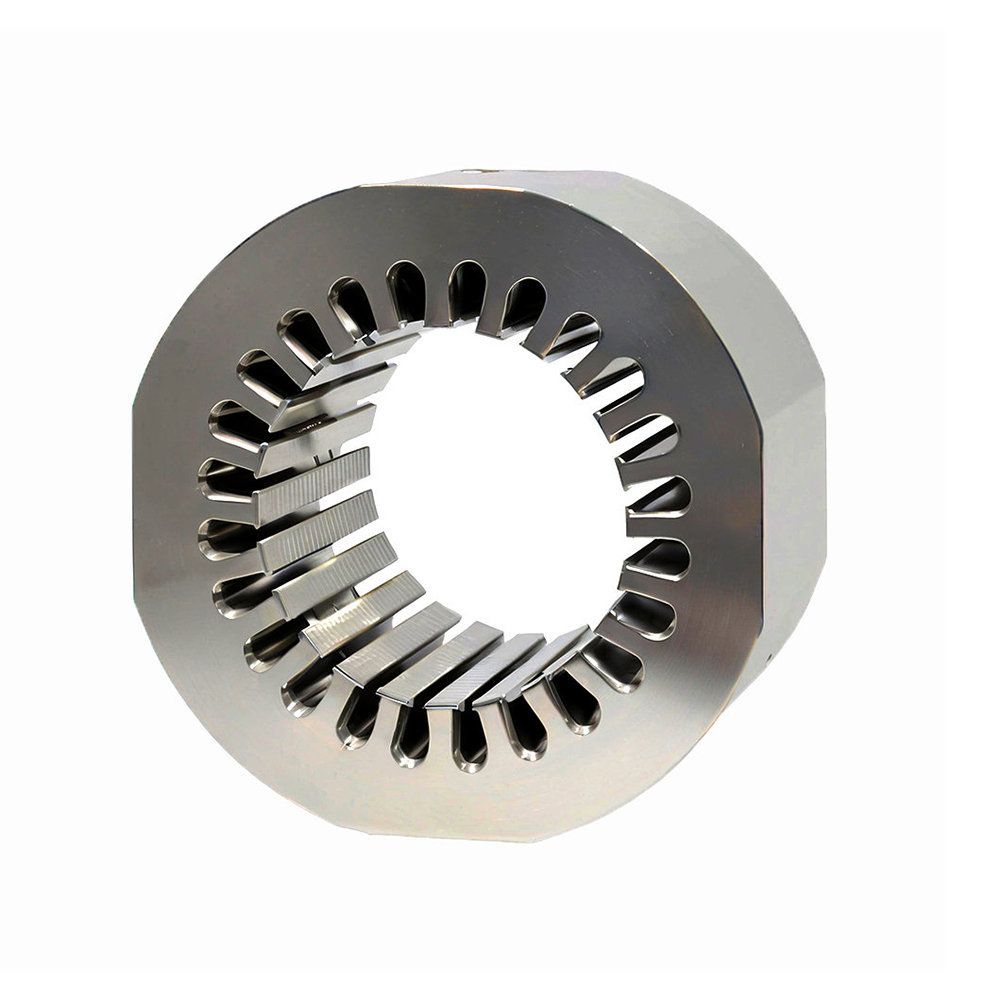

Full size coverage capability: from micro motors with an outer diameter of 50mm to 2000mm wind power stator cores, the full range of mold life exceeds 5 million strokes, material utilization rate reaches 97%, and the comprehensive cost is 18% lower than the industry.

Ultra-stable mass production guarantee: IoT system monitors the stamping tonnage curve in real time, the core weight tolerance is ±0.3%, and the magnetic flux density fluctuation is ≤2%, which completely solves the hidden dangers of abnormal noise and vibration of the motor. (2

2. Wide tonnage coverage: 110 to 800 types (110T-800T nominal force), suitable for stamping of cores with an outer diameter of 50-2000mm, supporting 0.2-3.0mm silicon steel, amorphous alloy and high-strength steel blanking, meeting the needs of home appliances, new energy, and wind power.

Gantry double-point structure: double crankshaft synchronous drive, anti-eccentric load capacity increased by 50%, dynamic parallelism ≤0.03mm/m under wide table (maximum 2500×1200mm), ensuring the contour accuracy of large-size stator punching ±0.02mm.

High-precision control: servo closed-loop system + German Rexroth guide rail, repeated positioning accuracy ±0.01mm, strokes up to 150 times/minute (110 type) to 30 times/minute (800 type), burrs ≤0.02mm, stacking coefficient ≥97.5%.

Intelligent production: IoT data platform monitors tonnage curve and mold stress in real time, predictive maintenance reduces downtime, mold life is increased by 30% (5-10 million strokes), and energy consumption is 40% lower than traditional models.

3. The core advantages of our iron core:

✅ High precision: axial runout after stacking ≤0.03mm, motor energy efficiency increased by 0.5%+;

✅ Low loss: burrs ≤0.015mm, iron loss reduced by 10%-15%, reaching IE6 standard;

✅ Fully adaptable: 50mm-2000mm full size coverage, material utilization rate 97%;

✅ Zero risk: IoT real-time quality control, weight tolerance ±0.3%, CPK≥1.67.