JH21-125 open type fixed table press

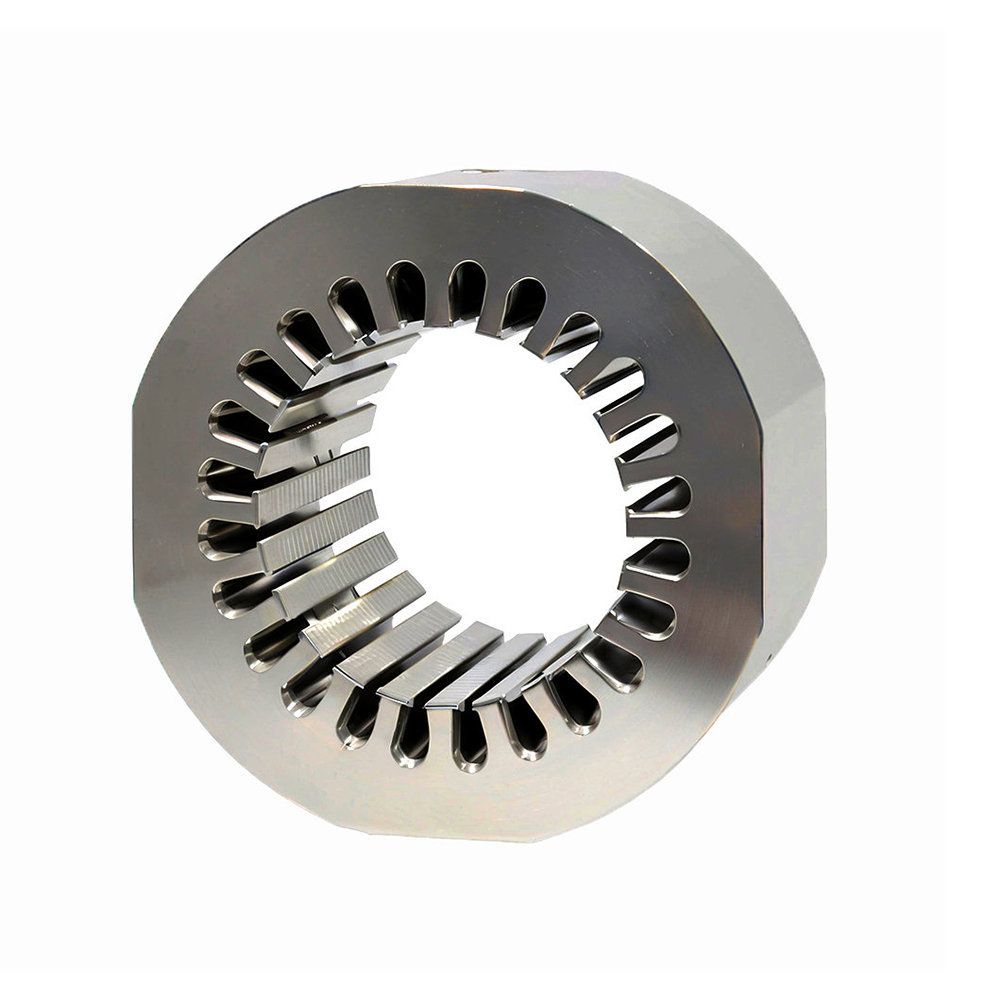

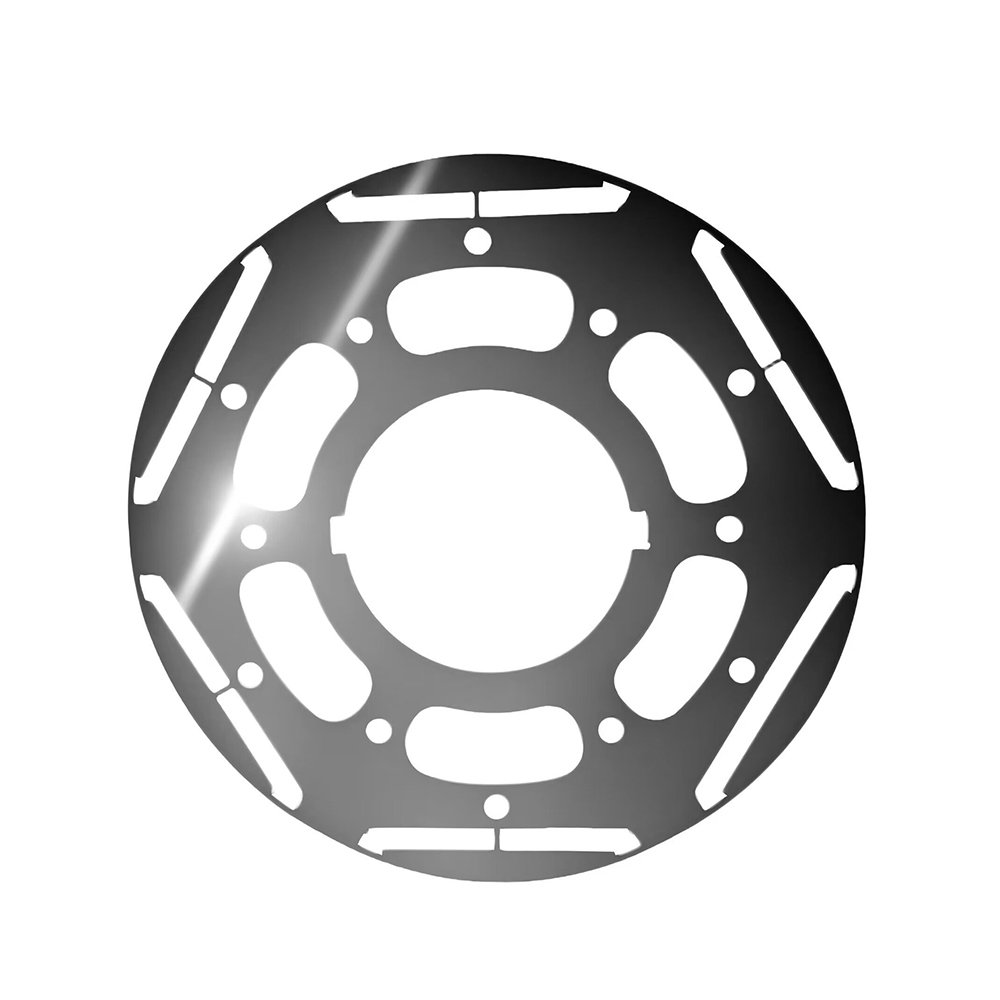

1. Our company uses JH21-125 open press, focusing on the production of economical motor cores and structural parts. The equipment punches 60-90 times/minute, with a repeat positioning accuracy of ±0.05mm, suitable for 0.35-0.5mm cold-rolled plates and silicon steel sheets. After manual adjustment, the burr of the punching sheet is ≤0.05mm (meeting basic industrial requirements), and the stacking coefficient is ≥0.92. The manual mold change time is ≤15 minutes, and manual sampling (caliper + feeler gauge) is performed every 30 minutes to ensure the dimensional tolerance of ±0.08mm and the flatness of ≤0.15mm/100mm. We have stably supplied 500,000 cores to a home appliance customer, with a pass rate of 98%. The mold cost is only 1/3 of that of a high-speed punch, and the material utilization rate is 90%. Supports flexible orders for small and medium batches, with a single-piece processing cost as low as 0.1 yuan/piece, suitable for small asynchronous motors, ventilation equipment and hardware housings, with a weight tolerance of ±1.0%, and an emergency delivery cycle of 96 hours, providing cost-effective solutions for cost-sensitive customers.

2. Core advantages

JH21-125 achieves low-cost punching mass production:

Punching times 60-90 times/minute, burrs ≤0.05mm after manual adjustment (0.35-0.5mm material thickness);

Dimensional tolerance ±0.08mm, stacking coefficient ≥0.92, suitable for home appliances and small motor cores;

Manual mold change ≤15 minutes, manual sampling pass rate 98%, material utilization rate 90%;

Mold cost savings of 70%, single-piece processing fee 0.1 yuan, 96-hour emergency delivery, meeting the economic needs of small and medium batches.