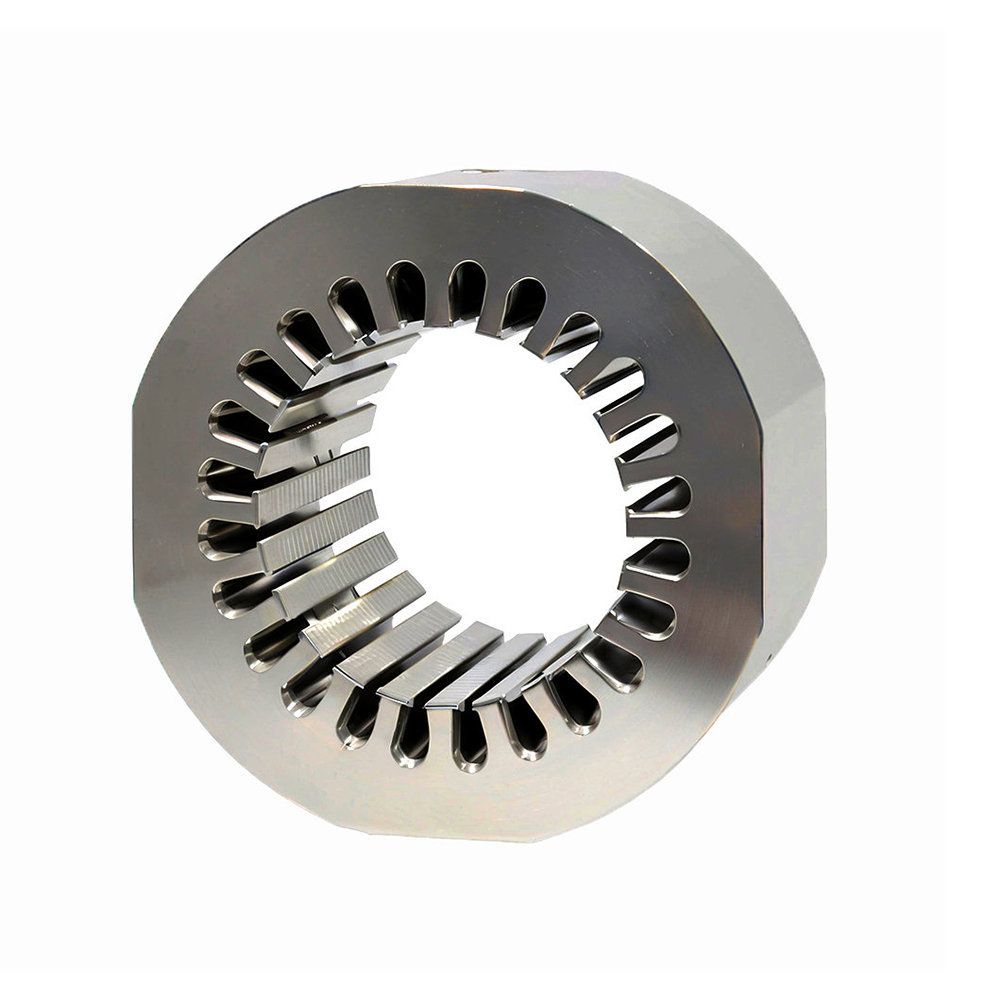

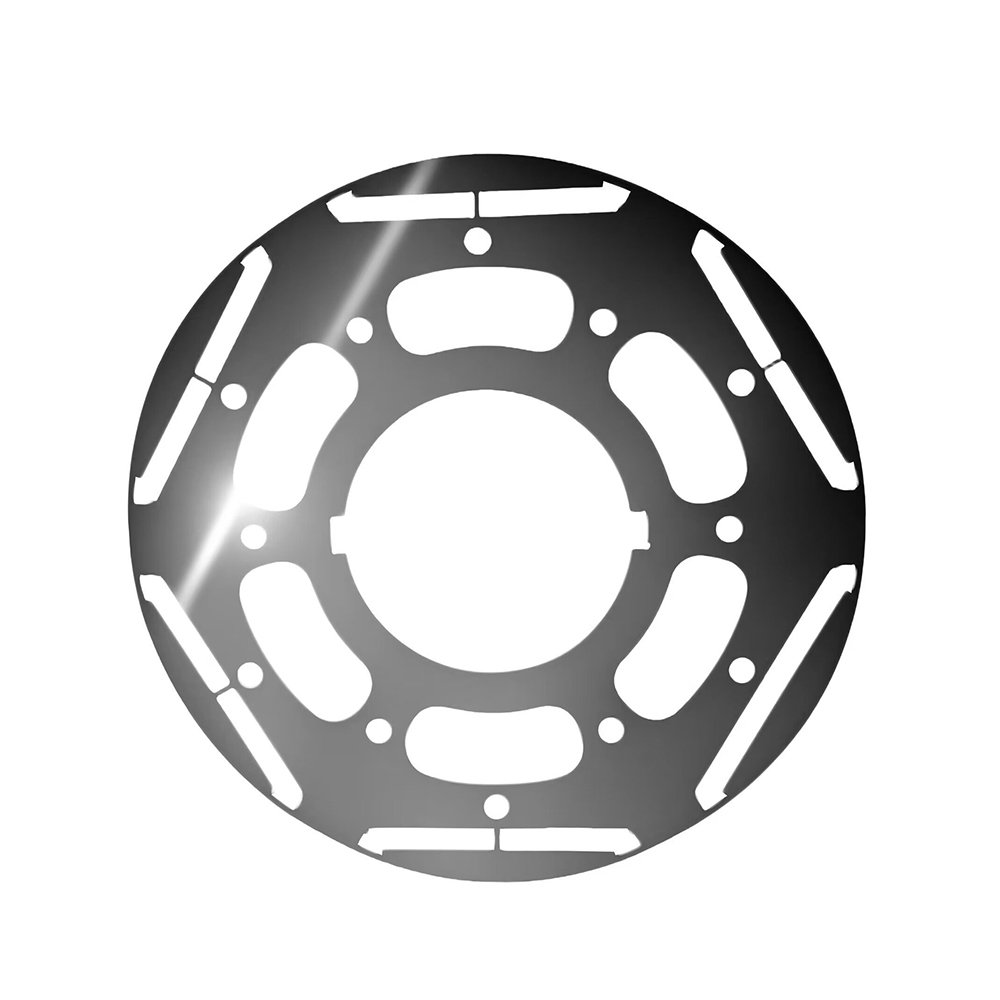

YPH series closed double-point rapid precision press

1. Relying on the YPH series closed double-point press, our company specializes in manufacturing high-precision motor cores. It can produce stator punchings with a maximum outer diameter of 800mm (supports 1200mm customization), contour tolerance ±0.015mm, burr ≤0.015mm, and stacking coefficient ≥98%. The equipment is equipped with an IoT intelligent monitoring system to track stamping parameters and mold life in real time, ensuring zero defects in the delivery of 3 million pieces in a row (verified by Taiwanese customers). Through dynamic compensation and multi-link speed change technology, the core iron loss is reduced by 10%-15%, helping to improve the energy efficiency of new energy motors by more than 0.8%, and saving 18% in comprehensive costs. 15-minute quick mold change, 55% energy saving ratio and 8 million punch mold life provide efficient and reliable solutions for industrial motors, home appliances and wind power fields. (About 150 words)

2. Our company uses YPH closed double-point press to produce motor cores, with a maximum outer diameter of 800mm, accuracy of ±0.015mm, burr ≤0.015mm, and stacking coefficient ≥98%. The IoT system monitors stamping data in real time, achieving zero defects in the delivery of 3 million pieces (Taiwanese customers), reducing iron core loss by 10%, and helping to improve motor energy efficiency by 0.8%. 15-minute die change, 55% energy saving and 8 million punch die life, comprehensive cost savings of 18%, suitable for new energy, wind power and high-end industrial motor fields.