Guia para iniciantes sobre motores de passo e como funcionam

Stepper motors, small yet powerful, transform electrical pulses into precise movements, making them essential in devices like 3D printers and CNC machines. Their key advantage lies in accurate positioning without extra sensors, utilizing magnets and electromagnetic induction to move in defined steps. With designs including permanent magnet, variable reluctance, and hybrid types, they cater to various performance needs. Cost-effective and easy to control, they require proper wiring, driver selection, and regular maintenance to avoid issues like overheating or skipped steps. The global demand continues to surge, driven by automation and miniaturization trends, promising a robust future.

A stepper motor is a special motor that moves in small steps. It moves each time you send it an electrical signal. You can control its movement very well. This makes stepper motors different from regular motors.

Stepper motors can move to spots with great accuracy. They can stop exactly where you want them to stop.

Many devices use stepper motors because they move in steady steps.

The world market for stepper motors is getting bigger. It may reach $8.33 billion by 2032.

| Tipo de motor | Cost Range (per axis) |

| Motores de passo | $40 - $80 |

| Servomotores | $150 - $300 (entry-level) / $500 - $1,000 (industrial-grade) |

If you need simple and repeatable movement, stepper motors are a good choice.

Principais conclusões

Stepper motors move in tiny, exact steps. This helps them go to the right spot without extra sensors. These motors work well when you need steady and repeatable moves. They are used in things like 3D printers and CNC machines. When picking a stepper motor, think about how far it needs to move. Also, think about how fast and accurate it should be. You should also check the place where it will be used. This helps you pick the best one for your project. Stepper motors can get too hot or skip steps. Doing regular checks and using the right settings can stop these problems. More people are buying stepper motors now. This makes them a good choice for many jobs and industries.

What Is a Stepper Motor

Simple Definition

A stepper motor is a special electric motor. It moves in small steps, not in a smooth spin. Each signal makes it turn a set amount. This helps you control its position very well. People use stepper motors in machines that need to move to exact places. Examples are 3D printers and robots.

Here are two formal definitions from engineers:

| Definição | Descrição |

| Stepper Motor | A brushless DC electric motor that turns in steps when you give it DC voltage. It works in open-loop systems. You can control its position by counting steps. |

| Stepper Motor | An electric motor that turns its shaft by a fixed number of degrees. This lets you track its angle without sensors. |

�� Tip: You do not need extra sensors for a stepper motor. You just count the steps to know where it points.

Key Features

A stepper motor has special features that make it useful. Here are some important ones:

Precise Positioning: You can move it to an exact spot. It can stop with accuracy as fine as ±0.05°. This is better than many other motors.

High Responsiveness: O stepper motor reacts fast to your signals. It moves with each pulse you send.

Strong Torque at Low Speeds: It gives good power at low and medium speeds. This helps when you need steady movement.

Long Lifespan: Most stepper motors last about 10,000 hours. Some last tens of thousands of hours if used right. If you use it for one eight-hour shift each day, it can last almost five years. Some motors can work up to 20 years, depending on the bearings and how you use them.

Simple Control: You do not need feedback systems or sensors. You just count the steps to know its position.

| Caraterística | Motores de passo | Other Motors (e.g., Servo) |

| Stopping Accuracy | ±0.05° (±1.4µm with ball screw) | ±10µm (ground), ±20µm (rolled) |

| Torque Characteristics | High in low/mid-speed range | Flat from mid to high-speed ranges |

| Responsiveness | High, operates synchronously with pulse | Delays due to feedback from encoder |

You may have some problems with stepper motors. Here are common issues and what causes them:

| Common Issue | Possible Causes |

| Stepper Motor Actuator Fails to Move | Wires not connected, bad drivers, wrong pulse signals, weak power, or something blocking it. |

| Excessive Noise or Vibrations During Operation | Load connections not lined up, old bearings, wrong settings. |

| Stepper Motor Actuator Overheating Issues | Too much current, not enough air, wrong driver settings. |

| Unexpected Shutdowns in Stepper Motor Actuators | Power problems, heat protection circuits, or software issues. |

You can avoid most problems by checking wires and keeping the motor clean.

Use the right settings for your project.

Note: How long your stepper motor lasts depends on how you use it and where you use it. Good care helps it last longer.

How a Stepper Motor Works

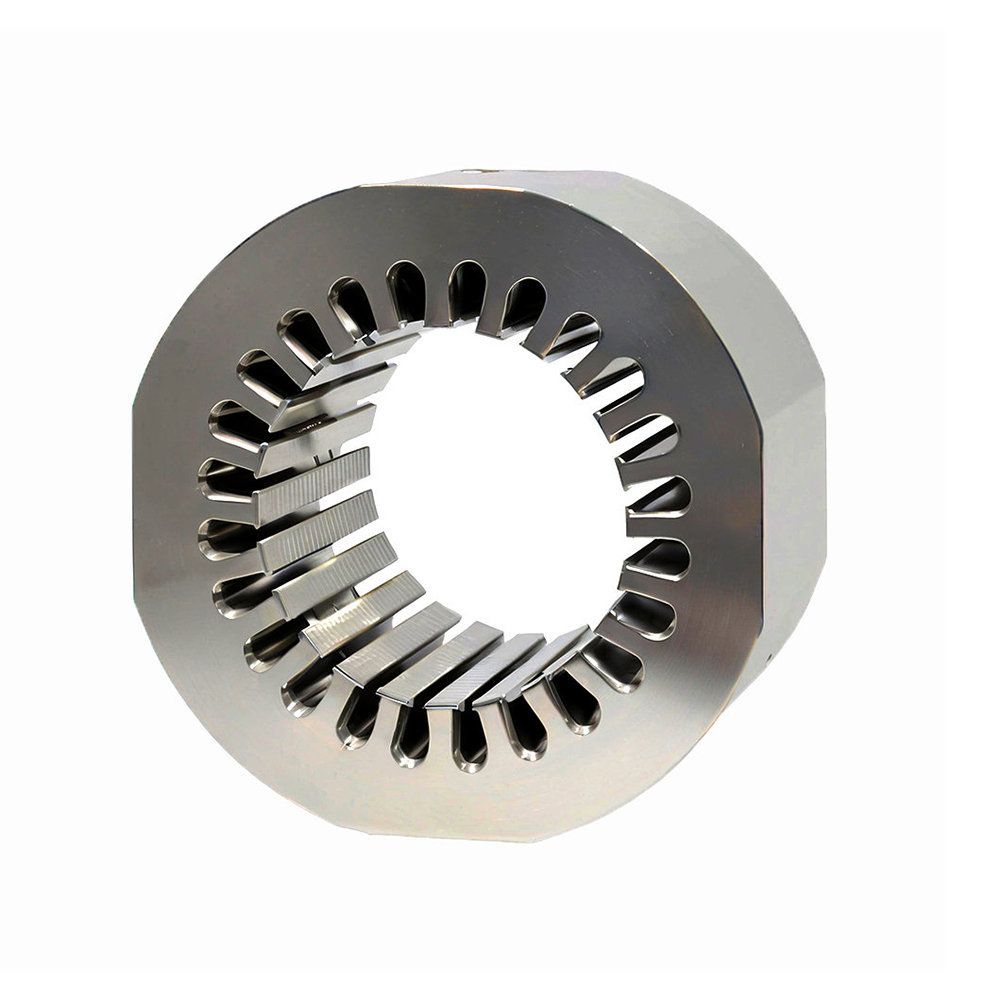

Structure: Rotor and Stator

Inside a stepper motor, there are two main parts. The rotor sits in the middle and spins when the motor works. It can be made from a magnet or a special iron core. Many stepper motors have three rotor pieces: rotor cup 1, rotor cup 2, and a permanent magnet. The magnet’s north and south poles run along the rotor’s length.

The stator goes around the rotor and does not move. The stator has many magnetic poles, often ten. Each pole has a wire coil wrapped around it. When electricity flows through the coils, the stator makes a magnetic field. This field pushes and pulls the rotor so it moves. The way the rotor and stator are built lets you control the stepper motor in small, exact steps.

Tip: The stator’s coils make the magnetic field that pulls the rotor into place. The number of poles and coils changes how many steps the motor can take in one turn.

Working Principle

A stepper motor moves in tiny, controlled steps. This happens because of how it works. When you send electric current to the stator coils, they make a magnetic field. This field pulls the rotor so it lines up with the stator. If you turn on the coils in a certain order, the rotor moves to the next spot. Each time you change which coil gets power, the rotor jumps to a new position. That is why a stepper motor moves in steps and not in a smooth spin.

"A stepper motor is a brushless DC motor that splits a full turn into equal steps. Regular motors spin all the time, but stepper motors move in small steps. Each step matches a certain angle. This makes them great for jobs that need exact movement or positioning.

The main way a stepper motor works is electromagnetic induction. When electric current goes through the stator coils, it makes a magnetic field. This field interacts with the rotor. By turning on the stator coils in a special order, the motor turns in small, controlled steps."

You control the stepper motor by sending electric pulses. Each pulse makes the rotor move a set angle, called a step. The size of each step depends on how the rotor and stator are built. Some stepper motors move 1.8° per step, so it takes 200 steps for one full turn. Others can move in even smaller steps for more control.

The rotor and stator work together to give the stepper motor its special movement. The stator’s magnetic field grabs the rotor and holds it until you send the next pulse. This lets you move the motor to exact spots without extra sensors.

| Characteristic Type | Descrição |

| Dynamic Characteristics | These affect how the motor starts or turns and change how fast it works. |

| Static Characteristics | These affect how the angle changes when stopped and change how accurate the equipment is. |

| Maximum Holding Torque (TH) | This is the most torque when the motor is powered but not moving. |

| Pullout Torque | This is the most torque the motor can make at each speed. |

| Angle - Torque Characteristics | This shows how angle and torque change when force is put on the motor shaft. |

A stepper motor uses power even when it is not moving. It needs current to hold its position. This can make the motor warm and less efficient than other motors, like servo motors, which only use power when moving or holding a load.

If you want to know how a stepper motor works, remember these points: The stator makes a magnetic field by powering its coils. The rotor lines up with this field and moves in steps as you change which coils get power. The motor works by electromagnetic induction and careful timing of the electric pulses. This design lets you control the motor’s position and movement very well.

Stepper Motor Types

There are three main stepper motor types. Each type works in its own way. Each one is good for different jobs. Learning about them helps you pick the right motor.

Permanent Magnet

Permanent magnet stepper motors have a magnet in the rotor. This design lets you control movement very well. It also gives strong torque at slow speeds. These motors are simple and work reliably. You can find them in robots and CNC machines. They are also used in 3D printers. Medical devices and electronics use them too.

| Characteristics | Aplicações |

| Precise control | Robotics |

| High torque at low speeds | CNC machines |

| Simple design for reliability and efficiency | 3D printers |

| Versatility | Medical devices |

| Essential in modern automation | Consumer electronics |

Tip: Permanent magnet stepper motors move smoothly and are easy to set up. Use them when you need things to be accurate and dependable.

Variable Reluctance

Variable reluctance stepper motors are the simplest type. The rotor has no windings. It is made of soft iron with teeth. The stator has coils that make a magnetic field. When you send power, the rotor moves to the easiest spot. These motors do not make detent torque. The rotor is not a magnet.

The rotor uses soft iron and has many teeth.

The stator is made from silicon steel and has coils.

The rotor’s spot depends on the teeth and reluctance.

The stator has an even number of poles for easy starting and two-way turning.

These motors have less torque but keep it at faster speeds.

They can be noisy, so they are not good for quiet places.

Note: Variable reluctance stepper motors are good for learning. You can use them for jobs that need medium or fast speed.

Hybrid

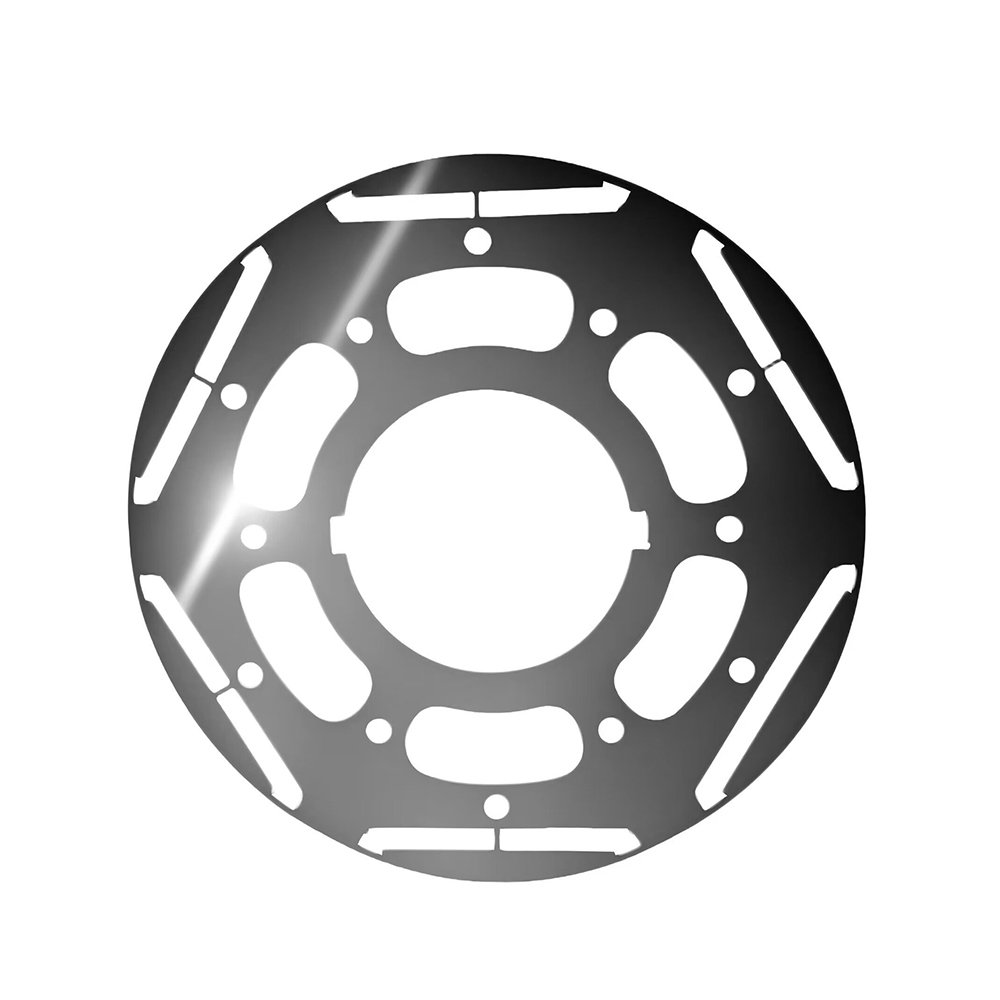

Hybrid stepper motors mix features from the other two types. They give high resolution, speed, and torque. The rotor has teeth and is magnetized along its length. This design works better but costs more.

| Caraterística | Hybrid Stepper Motors | Permanent Magnet Motors | Variable Reluctance Motors |

| Torque | Increased detent, holding, and dynamic torque | Moderate torque | Lower torque |

| Step Resolution | Higher resolution (0.9°, 1.8°) | Moderate resolution | Lower resolution |

| Speed | Suitable for speeds under 1,000 rpm | Higher speed capabilities | Limited speed capabilities |

| Construction Complexity | More complex due to hybrid design | Simpler construction | Simpler construction |

| Custo | Higher cost due to complexity | Moderate cost | Lower cost |

Hybrid stepper motors are best for jobs needing top accuracy and torque. They work well in advanced machines and equipment.

Tip: Hybrid stepper motors give the best results. Pick them for tasks that need careful control and strong power.

Stepper Motor Wiring

When you work with a stepper motor, you need to know how to connect its wires. The wiring affects how the motor runs and how much control you have. You will see three common wiring setups: 4-wire, 6-wire, and 8-wire. Each type gives you different options for connecting to drivers and for controlling movement.

4-Wire

A 4-wire stepper motor is simple to connect. You have two coils inside the motor. Each coil has two wires. You connect A+ and A- to one coil, and B+ and B- to the other coil. You can find the wire pairs by checking the datasheet, using an ohmmeter, or twisting wires and feeling for resistance changes. This setup works well with many drivers, such as the Buildbotics CNC Controller.

Two coils, each with two wires

Easy to identify wire pairs

Works with common drivers

Tip: Always check the motor’s datasheet before wiring. This helps you avoid mistakes and keeps your stepper motor safe.

6-Wire

A 6-wire stepper motor gives you more choices. Each coil has three wires: two ends and a center tap. You can use the center tap for unipolar operation. In unipolar mode, you connect the center wire to power. This lets current flow in one direction through each half of the coil. If you want more torque, you can ignore the center tap and use bipolar mode. In bipolar mode, you energize the whole coil in both directions.

You can switch between unipolar and bipolar modes. This flexibility helps you match the motor to your project’s needs.

8-Wire

An 8-wire stepper motor offers the most wiring options. You can connect the wires in series or parallel. This changes how the motor performs at different speeds. The table below shows how each wiring method affects torque:

| Wiring Configuration | Torque at Low Speeds | Torque at High Speeds |

| Unipolar | Moderate | Moderate |

| Bipolar Half Coil | Moderate | Good |

| Bipolar Series | Elevado | Moderate |

| Bipolar Parallel | Elevado | Elevado |

CNC mills need high torque at low speeds. Bipolar series wiring works best for these machines.

If you need very high speed, bipolar half coil wiring gives better results.

Note: The 8-wire stepper motor lets you choose the best setup for your application. You can adjust wiring to get the torque and speed you want.

Stepper Motor Control

Control Signals

Control signals tell the stepper motor how to move. These signals decide the steps and direction. The most common signals are pulse signals and direction signals. Each pulse makes the motor move one step. The direction signal shows which way the motor turns. You can send many pulses every second with a modern controller. This helps you change speed and position fast.

Control signals can look different. You might use pulse width modulation (PWM) to change power by making each pulse wider or thinner. Sinusoidal control uses a smooth wave to help the motor run quietly and accurately. Some systems use single-ended PWM, which sends square waves. Others use differential PWM, which sends two waves for better control.

| Control Signal Type | Descrição |

| Pulse Width Modulation (PWM) | Changes pulse width to control power, often from microcontrollers. |

| Sinusoidal Control | Uses a sine wave for smooth and accurate control. |

| Single-ended PWM | Sends square-wave signals with a set frequency. |

| Differential PWM | Uses two waveforms for more precise control. |

Tip: You can use a microcontroller to make control signals. This lets you control speed and direction easily.

Drivers and Microcontrollers

A driver connects your control signals to the motor. The driver takes the signals and sends the right voltage and current to the motor coils. You need a driver because a microcontroller cannot give enough power alone. Different drivers give you different control and performance.

| Driver Type | Pros | Cons |

| L/R (Resistance-Controlled) | Simple and cheap design | Not good for high speeds |

| Chopper (Constant Current) | Works efficiently | Circuit is more complex |

| Microstepping Drivers | Makes motion very smooth | May lower torque at small steps |

| Intelligent Stepper Drivers | Gives real-time diagnostics | Costs more |

You can use a microcontroller, like a PIC16F877A, to make control signals for the driver. The microcontroller lets you program how the motor moves. It turns on the driver, which powers the motor. You can set speed, direction, and step size in your code. The stepper motor controller uses both the microcontroller and driver for exact control.

Microcontrollers make control signals in the right order.

The driver boosts these signals to move the motor.

You can program the microcontroller for special control jobs.

Note: You get the best results when you pick the right driver for your motor and control needs.

Choosing a Stepper Motor

Selection Factors

When you pick a stepper motor, you need to think about a few things. You want the motor to fit your project. First, figure out how far the motor needs to move. Next, decide how fast it should get there. You also need to know how exact the movement must be. Some projects need tiny steps. Others can use bigger steps.

Here are some important things to check:

* How far the motor travels

* The most time allowed for moving

* How exact the motor stops

* If the motor goes past its target

* Time for the motor to settle after moving

* Step resolution, based on step size and design

* Friction in your setup

* Inertia, which affects starting and stopping speed

* Needed speed and torque

* Torque-to-inertia ratio for quick starts

* Extra torque for better performance

You should also think about where you will use the motor. High heat can make the motor get too hot and work less well. Humidity and dust can shorten the motor’s life. If you work in tough places, pick a motor with a high IP rating. This protects it from water and dust.

Tip: Always choose a stepper motor that matches your project and the place you will use it.

Common Applications

Stepper motors are used in many fields. They help machines move with accuracy and repeat steps. Here are some ways people use them:

3D printers use stepper motors to control the print head and bed.

CNC machines use stepper motors for cutting and shaping.

Robots use stepper motors for exact moves and strong power.

Stepper motors are also found in electronics and automation. For example, smartphone cameras use tiny stepper motors for quick and sharp focus. Labeling machines in food and drug factories use stepper motors for better speed and accuracy.

| Aplicação | Descrição | Precision |

| Smartphone Camera AF (iPhone) | Tiny stepper motor, fast focus, no shutter delay | ±0.05° |

| Inline Labeling Machines | More accurate labels and faster work | ±0.5 mm |

You can see that stepper motors help many devices work better and more often.

A stepper motor turns electrical pulses into exact steps. This lets you control position very well. You get low mistakes and save money on many projects. When picking a stepper motor, think about how you want it to move. Also, consider speed, weight, stepper mode, and wiring.

You can read guides like All About Stepper Motors. You can also take classes such as Mastering Stepper Motors: An Arduino Robotics Course to learn more.

Stepper motors are getting smarter and smaller. They are also becoming stronger. Try using them and see what you can make!

FAQ

What makes a stepper motor different from a regular motor?

Stepper motors move in small steps. You control each step with an electrical pulse. Regular motors spin smoothly. Stepper motors let you set exact positions. You do not need extra sensors.

Tip: Use stepper motors when you need precise control.

Can you run a stepper motor without a driver?

You cannot run a stepper motor directly from a microcontroller. The driver boosts the signals and gives enough power. Always use a driver to protect your motor and get smooth movement.

How do you choose the right stepper motor for your project?

Check your project’s speed, torque, and accuracy needs. Look at the motor’s step angle and wiring type. Match the motor to your working environment. Use datasheets for details.

| Fator | What to Check |

| Speed | Needed RPM |

| Torque | Load weight |

| Accuracy | Step angle |

Why does a stepper motor get hot during use?

Stepper motors use power even when they hold position. This makes them warm. High current or poor airflow can cause overheating. Make sure you use the right settings and keep the motor cool.

What are common problems with stepper motors?

You may see missed steps, noise, or overheating. Check your wiring, driver settings, and power supply. Clean the motor and use correct settings to avoid most issues.

Note: Regular checks help your stepper motor last longer.